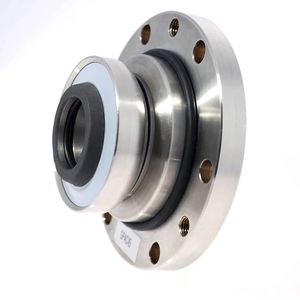

Circular seal LAMELFLEX®graphitePTFEfor butterfly valves

Add to favorites

Compare this product

Characteristics

- Configuration

- circular

- Material

- graphite, PTFE

- Application

- for butterfly valves

- Temperature limit

Min.: -196 °C

(-321 °F)Max.: 500 °C

(932 °F)- Pressure limit

150 bar

(2,175.6 psi)

Description

LAMELFLEX®, a unique laminated seal, is designed for critical service applications and dedicated to achieving the highest efficiency for your triple offset butterfly valves by significantly reducing internal leak paths. With state-of-the-art engineering, our LAMELFLEX® seals form a strong seal against rigid valve seats and deliver optimal cycle frequency and fire safety. Through thoughtful design and precise manufacturing, this product can achieve bidirectional ANSI Class VI shut-off, the most stringent leakage performance standard as tested with liquid nitrogen.

Features & Benefits

The benefits obtained by using LAMELFLEX® seals result from:

Complete analysis of the valve – hardware interface with the seal

Understanding the interaction between the different materials and their behaviors

Taking into account seal assembly in the valve manufacturing process

Understanding the effects related to the direction of fluid flow including bidirectional operation

Rigorous selection of the appropriate machining method to ensure dimensional tolerances and good surface finish at the valve seat.

Special designs available with diverse materials according to specifications

Lamination of special material (graphite, PTFE) and metal, offering a combination of compressible and resilient materials

Available in sizes from 25.4 mm to 2,438.4 mm (1 inch to 96 inches)

Can achieve bidirectional ANSI Class VI shut-off, the most stringent leakage performance standard as tested with liquid nitrogen

LAMELFLEX®, a unique laminated seal, is designed for critical service applications and

Catalogs

No catalogs are available for this product.

See all of Technetics Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.