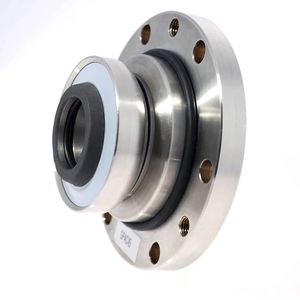

Circular seal stainless steelindustrialshaft

Add to favorites

Compare this product

Characteristics

- Configuration

- circular

- Material

- stainless steel

- Application

- industrial, shaft

- Other characteristics

- radial, labyrinth

Description

Technetics Group Brush Seals – Designed to increase airflow efficiency in engines and compressors

Replacing labyrinth seals with brush seals from Technetics Group can reduce leakage by 5 to 17 times, thus providing significant turbomachinery efficiency and output gains.

Brush seals work by absorbing the radial deflections between the shaft and rotor during transient operation. The seal then follows the rotor back to the steady-state operating position to maintain minimum leakage. The brush pack is composed of thousands of finely packed 2.8 to 5.6 mil diameter wire bristles. The bristle material, a cobalt or nickel alloy, is selected to provide an optimal combination of wear properties and oxidation resistance. The backplates and side plates are typically fabricated from stainless steel or nickel alloys. The primary consideration is the thermal expansion and contraction of the case material.

Brush seals can be delivered as a single unit or in multiple segments. The bristles can be configured radially inward, radially outward or axially.

Features & Benefits

Benefits:

Reduced wear rate means longer life

Consistent flow provides predictable performance

Higher-pressure operation yields flexibility in design

Reduced heat generation ensures a cooler rotor

Speak with a Specialist

Product Applications

Aerospace Industry

Industrial Turbines

Marine Engines

Catalogs

No catalogs are available for this product.

See all of Technetics Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.