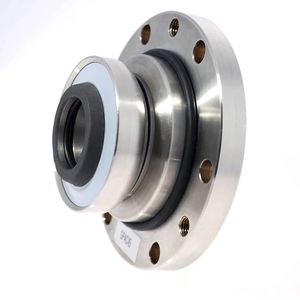

Circular seal HELICOCARB®metalcarbonfor rotating shafts

Add to favorites

Compare this product

Characteristics

- Configuration

- circular

- Material

- metal, carbon

- Application

- for rotating shafts, for pump, bearing, industrial, gearbox, for gearbox, for compressors, for aerospace applications, engine, shaft

- Fluid

- air, gas

- Other characteristics

- dynamic, custom

- Temperature limit

Max.: 450 °C

(842 °F)- Pressure limit

Max.: 2 bar

(29 psi)- Diameter

Max.: 5,000 mm

(196.85 in)

Description

High-performance rotating sealing solutions for critical industrial applications.

The HELICOCARB® carbon brush seal, robust and easy to integrate, offers good adaptability to your service and operating conditions as well as performance improvements for your equipment. This sealing solution also allows you to reduce your total cost of ownership while ensuring the safety and reliability of your installation.

HELICOCARB® is a circular brush-seal whose internal diameter, in contact with a rotating shaft, consists of a carbon brush. A patented assembly enables it to efficiently compress a network of soft carbon bristles. A circular brush is created, with every bristle oriented towards the center of the seal. The arrangement of the assembly and the specific Technetics manufacturing process results in a high-quality carbon brush seal, whose performance is very consistent.

Features & Benefits

Improved overall equipment energy efficiency:

Leakage reduction: up to 90% gain compared to labyrinth seals (depending on conditions)

Low-friction torque resistance

Low shaft abrasion

Simple, robust and reliable

Easy to integrate and easy to install

Customizable design for optimized integration within assembly (materials casing, carbon fiber layer)

Improved lifetime

Bi-directional

HELICOCARB® Seal close up

HELICOCARB® Seal front view

HELICOCARB® Seal

HELICOCARB® Seals

Speak with a Specialist

Product Applications

The HELICOCARB® seal can replace existing seals in the following applications:

Centrifugal gas compressor

Aero engine

Bearing protection

Centrifugal pump

Industrial air fan

Gearbox

Catalogs

HELICOCARB®

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.