Aluminum seal rubberelastomersilicone

Add to favorites

Compare this product

Characteristics

- Material

- aluminum, rubber, elastomer, silicone, FKM

- Application

- gearbox, profile, vacuum

- Fluid

- oil, air

- Other characteristics

- hydraulic, static, dynamic, high-pressure

- Pressure limit

200 bar

(2,900.8 psi)

Description

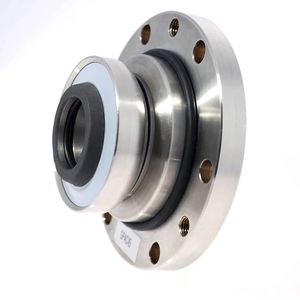

Overmolded plate seals

Elastomer seals (FKM, silicone, fluorinated silicone) can be overmolded within grooves on anodized aluminum or nickel-plated supports. This enables perfect positioning between elements to be sealed, independently of the orientation and accessibility of the seal.

Features & Benefits

Simple, visually & verifiable installation (correct location of the rubber part in front of the sealing surface)

High-pressure performance (more than 200 bars as well as vacuum)

Easy maintenance even in a vertical position with very low space between flanges

Multi-port sealing with one component

Ability to seal complex flange geometry.

Solid metal-to-metal contact insures stable joint with no re-torque required

Redundant seals can be incorporated into one component

No machined grooves required in mating flanges

Different rubber and materials (and coatings) retainers: FKM, Silicone and Fluorosilicone seal materials

Specific design features (metal-to-metal design, special seal profile) contribute to safe static sealing of aircraft fuel systems

Can also be used in dynamic applications (relief valve, poppet valve)

Plate Seals

Plate Seals

Plate Seal

Speak with a Specialist

Product Applications

Aircraft engines:

Sealing on compressors, pumps & gearbox assemblies

Sealing on flanges and connections of air, oil & fuel management systems

High sealing pressure on Kerosene post combustion’s hydraulic device

Hydrogen production:

Sealing on separation stacks

Nuclear:

Sealing on primary pumps filters

Catalogs

No catalogs are available for this product.

See all of Technetics Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.