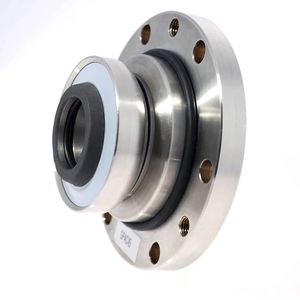

Spiral gasket VITAFLEX® graphitePTFEflange

Add to favorites

Compare this product

Characteristics

- Type

- spiral

- Material

- graphite, PTFE

- Application

- flange, valves, metal

Description

A large variety of the most difficult sealing problems can be solved using VITAFLEX® spiral wound gaskets. Although its basic fundamental principle has changed little since its creation, production techniques and the materials developed and used over the last 30 years have enabled our gaskets to be adapted to a much broader range of applications. We can offer optimized gaskets adapted to our customers’ specific requirements including operating conditions, sealing, dimensioning of assemblies and safety level. The winding, or the active part of the gasket, consists of an alternating combination of the formed metal strip and the soft filler material wound together. The soft filler material is selected to suit the medium which is to be sealed off (pressure, temperature, fluid). Several consecutive turns of the metal strip are welded together at the beginning and end of the winding in order to maintain the tension.

Features & Benefits

Design adaptable for all types of assemblies

Wide choice of materials (Inox, INCONEL®, Monel, PTFE or fibers)

Standard range meets the requirements of flange standards ASME B16.5 or NF EN 1759-1 but also NF EN 1092-1

Vitaflex Seal

Vitaflex PTFE Seal

Vitaflex graphite seal

Vitaflex Seal

Speak with a Specialist

Product Applications

Chemical & Petrochemical Industry: catalytic synthesis, heat exchangers, vessel gaskets, piping, valves, and storage

Nuclear Industry: cooling systems, valves, manholes, handholes, and heat exchanger with or without partition walls

General Industry: high and low-pressure steam systems, autoclaves, heat exchangers, heat transfer fluids, high pressure, hydraulic piping, valves, compressors and pumps

Catalogs

ORIGRAF®

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.