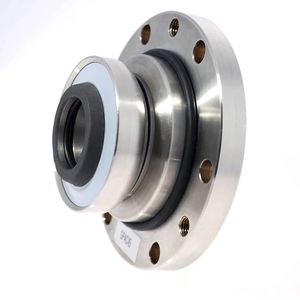

Carbon seal Qualiseal®compressionhousingshaft

Add to favorites

Compare this product

Characteristics

- Material

- carbon

- Application

- compression, housing, shaft

- Fluid

- oil, gas

- Other characteristics

- spring

Description

In certain extreme applications, a part made of individual segments may meet your critical performance requirements better than a single-piece unit.

Segmented seals ride directly along the shaft and are primarily used in low-pressure applications.

These seals contain a series of segmented carbon rings which contact the shaft or rotor. Segments inside the seal housing are kept in the proper location by anti-rotation keys or pins. A secondary seal is formed by the axial spring loading of the seal rings against the internal surface of the housing face. During movement, a continuous seal is always in contact with either the primary or secondary sealing surfaces.

Features & Benefits

Benefits:

Tolerance to unlimited shaft axial movement

Prevents oil and contaminant migration into the process gas side

Leakage rates remain constant over the life of the seal

Features:

Rides directly along the shaft

Special gap segments permit the seal to adjust dimensionally for minimal leakage

Compression and garter springs ensure that segments remain in contact with mating surfaces during low delta pressure and shutdown conditions

Design Configurations:

Various seal ring segment configurations

Pressure-balanced segments

Fractured rings

Multiple seal labyrinth

Internally pressurized seal

Internally vented seal

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.