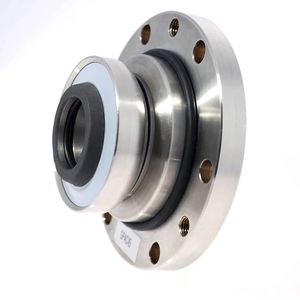

Spring-loaded seal Qualiseal® Controlled Gap/Bushingcarbonhousingshaft

Add to favorites

Compare this product

Characteristics

- Type

- spring-loaded

- Material

- carbon

- Application

- housing, shaft

- Fluid

- oil, air

- Other characteristics

- spring

Description

Really two pieces in one, Qualiseal® Controlled Gap/Bushing seals are the best solution when pressure is an issue.

Controlled gap or bushing seals are comprised of a carbon insert that is shrink-fitted into a separate retaining band. This floating circumferential ring assembly grows at a rate similar to that of the shaft when exposed to elevated temperatures.

Under normal operating conditions, the pressure on the airside is higher than the pressure on the oil side. This creates some air leakage through the controlled gap between the carbon ring and shaft. The differential air pressure, along with the spring load, provide the closing force necessary to maintain contact between the carbon and housing secondary sealing face. Meanwhile, the shaft turns freely within the carbon ring.

The seal design also features a unique stabilizer ring with fins which minimize stress on the carbon ring, thereby maintaining the roundness of the circumferential ring assembly. The dimensional tolerance of the critical inside diameter of the bushing ring is tightly controlled to minimize leakage variations.

Features & Benefits

Benefits:

Minimal leakage in an exceptionally wide temperature range

Tolerance to unlimited shaft axial movement

Very long life

Very low heat generation

Features:

Rides on a buffer that centers the ring and minimizes seal-to-shaft contact

Available in a wide variety of materials suitable to a broad range of applications

Often paired with other seals to create sealing systems that meet demanding requirements

Design Configurations:

Single seal for dual pressure conditions

Spring-loaded double back-to-back seal

VIDEO

Catalogs

No catalogs are available for this product.

See all of Technetics Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.