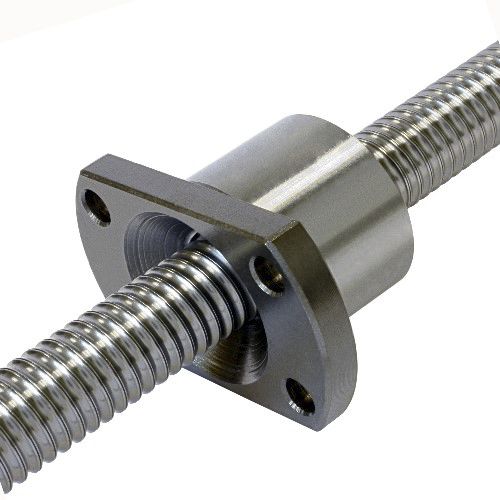

Ball Screws and Ball Screw Nuts

Properties

• Standard products are Ø 12 to Ø 40 mm, right-hand thread, nuts with double-sided flange cut and preload of P0

• Material: steel 50CrMo5QT, surface hardened 58-62HRC, hardening depth 2 mm from thread root

• In the following overview, the preferred types which are mostly available from stock are marked in red

• Higher preloads, ground screws, round nut flanges, etc. are available on request

• A higher preload of the nut enables a more precise positioning but leads to less efficiency

• Ball screw sets with preload P1 to P4 are delivered only in their assembled state. For preload P0, we deliver the screw and nut separately.

• End machining for fixed and floating bearings made according to your drawings are available on request. For examples, refer to pages V 061 and V 062

• Note that screws can buckle when installed vertically and placed under pressure or lifting loads

• Take the screw torsion into account when operating at high turning speeds

Advantages

• Rolling friction in the thread – thus very high efficiency

• Suitable for high speeds

• High positioning accuracy

• Lubrication required – usually nuts with lubrication hole

• No self-locking! Vertical ball screw sets must be mounted with brake motors