•Accuracy with high dosing rates.

•Constant quality of dough and fast changes of recipes.

•Absence of dust and contamination.

•Automatic lots tracking.

•Easy cleaning and maintenance.

•Homogenization of bulk products through specific rotation.

•Dosage from one to unlimited ingredients - even simultaneously.

APPLICATIONS

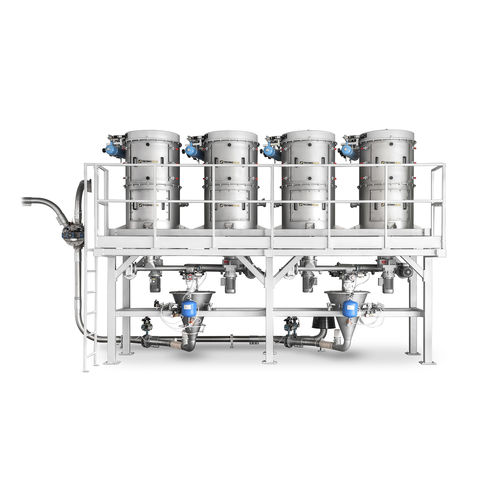

Automated dosing of minor ingredients when mass production requires highly accurate, consistent and repetitive blends with complete control and traceability at all times.

FUNCTIONING

The storage hopper can be fed by bags or big bags, manually or by mechanical or pneumatic systems, and sieved individually.

Custom extractors and homogenization systems then ensure reliable transfers - even for components with sliding difficulties.

Ingredients are automatically dosed according to the pre-set quantities on the PLC interface using an inverter-controlled dosing screw.

The screw can directly feed a weighing hopper (gain in weight). Alternatively, products can be extracted in the desired quantity from the storage hopper (loss in weight dosage), allowing the simultaneous dosage of several ingredients and faster batch preparation.

The weighing units deliver the high levels of accuracy that guarantee consistently high-quality production while reducing waste.

Finally, the product is pneumatically conveyed from the hopper to the dough mixer or to the blender.

TECHNICAL DATA

•Accuracy up to 1g.

•Flow rates from 0.3 l./h. to 1,000 l./h.

•Storage volumes up to 5,000l.

•Complies with the Atex 94/9/CE directive.

ACCESSORIES

•Pneumatic load.

•Dedicated sieving.

•Integrated or centralized dedusting.

•Reception from bags or big bags.