Continuous industrial fryer meatfor snacksfor fish

Add to favorites

Compare this product

Characteristics

- Type

- continuous

- Food product

- meat, for snacks, for fish

- Other characteristics

- conveyor, stainless steel, steam

Description

This fryer has been specifically developed to extend the useful life of oil

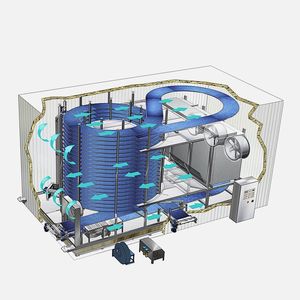

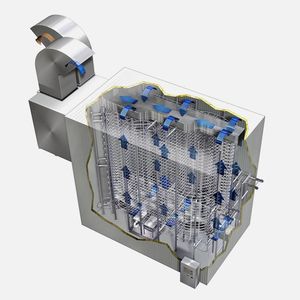

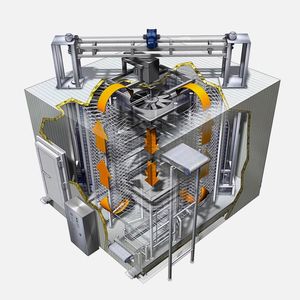

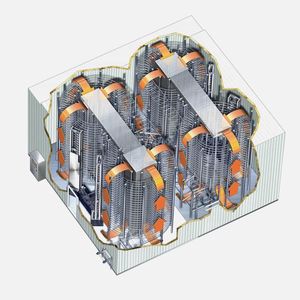

Diathermic oil industrial fryer, with a conveying system studied for each product according to client requirements. This allows us to satisfy the needs of even the most diversified sectors, such as meat, fish, breaded goods, snacks, peanuts, confectionery and pet food alike. This fryer has been specifically developed to extend the useful life of oil or frying fat.

Frying

CONSTANT ELIMINATION OF REMAINS FROM THE BOTTOM OF THE MACHINE

thanks to a bottom-cleaning system during frying;

MINIMAL JUMPS BETWEEN THE FRYING TEMPERATURE AND THE TEMPERATURE OF THE THERMAL EXCHANGE

thanks to the radiator submerged in the frying tank;

SIMPLE CLEANING

thanks to the tank extraction system that makes it easy to access, without any obstacles;

PRECISION IN MONITORING THE LEVEL OF FRYING

thanks to an electronic system that also automatically manages the filling, emptying and self-cleaning phases;

PRECISION IN MONITORING THE TEMPERATURE

of one or more areas of the fryer through the modulating three-way mixing valve(s), managed electronically;

ELIMINATION OF FUMES AND RE-ACCUMULATION OF STEAM IN THE OIL

thanks to an effective and silent hood system with inspection panels, stainless steel filters and forced extraction.

MANAGED ELECTRONICALLY AND IS SUITABLE FOR INTEGRATION

into existing production lines or into a complete Tecnopool line.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tecno Pool‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.