CAD software MDESIGN gearboxdevelopmentcalculationdata exchange

Add to favorites

Compare this product

Characteristics

- Function

- CAD, development, calculation, data exchange, data transfer

- Type

- 3D

Description

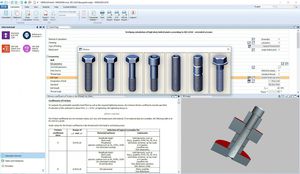

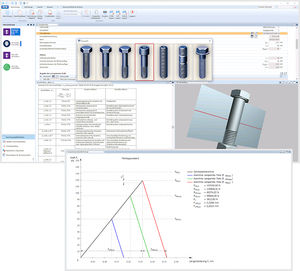

MDESIGN gearbox allows for the rapid combination of machine elements and immediate evaluation as an assembly comprising shafts, their bearings and gears. Intuitive modelling with the 3D assistant leads to complete calculation of all components used in one go. Data transfer is therefore no longer necessary between the individual calculations. The result - both for new developments and for modifications to existing assemblies - is enormous time savings.

Prototype development with software-supported optimisation methods

Depending on the development stage for the module, MDESIGN gearbox is suitable for use for the quick assessment of new and existing components through to the optimisation of multi-stage gearbox designs. In this case, integrated optimisation processes relating to mass and installation space, volume or inertia can be used. A variant can be selected directly, or various proposals can be compared with one another.

From big to small: detailing for a production-ready result

The finished gearbox design then allows for a multitude of options for optimisation of the macro and micro-geometry. Determination of the gear modifications taking the gearbox elasticities into account and semi-automatic calculation of the housing rigidity constitute the range of options with MDESIGN gearbox in combination with the load distribution modules (LVR). Seamless data exchange with all common CAD systems can be optimally implemented by means of structured STEP models.

Catalogs

MDESIGN overview of modules

4 Pages

Related Searches

- Analysis software solution

- Process software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Interface software

- Quality software

- Simulation software

- Programming software

- Automated software

- Development software

- Machine software

- Engineering software

- 2D software

- Safety software

- Calculation software

- Construction software

- Graphic software

- Architecture software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.