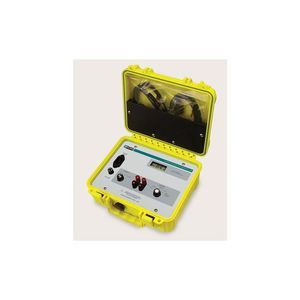

Digital microhmmeter 1750bench-top4-wire

Add to favorites

Compare this product

Characteristics

- Display

- digital

- Portability

- bench-top

- Other characteristics

- 4-wire

- Resistance range

Min.: 0 Ohm

Max.: 20,000,000 Ohm

Description

Recognized as the industry’s fastest precision microohmmeter, the model 1750 microohmmeter by TEGAM has become the #1 choice in manufacturing environments. Fuse manufacturers use it for nondestructive tests where the unmatched precision increases the process yield to the point where the 1750 pays for itself in weeks. The vast majority of resistors less than 1 Ohm are tested and sorted to accuracy better than 0.1% by the 1750. Automotive suppliers use it to consistently meet stringent quality requirements of welds, bonds and electrical connection in sub-assemblies. Aircraft manufacturers employ the 1750 microohmmeter to measure wiring harnesses and RF shields for connection integrity. The capability of the 1750 enables the accurate real-time measurement of electro-plating thickness and conductive coatings on housings and shields.

TEGAM’s 1750 microohmmeter employs multiple techniques to achieve its impressive accuracy. A four-wire kelvin technique eliminates the effects of lead resistance while offset compensation removes the errors caused by thermal contact voltages. The 1750 even monitors its performance over time and adjusts its calibration against a set of internal low temperature coefficient resistors in order to ensure consistent measurement performance without constant recalibration.

TEGAM specializes in low resistance measurement. Our technical sales staff and applications engineers understand both the measurement challenges you face and your manufacturing environment.

Catalogs

1740/GPIB

5 Pages

Related Searches

- Measuring machine

- Calibration system

- Portable testing system

- Digital testing system

- Industrial testing system

- Portable calibration system

- Temperature calibration bench

- Power meter

- Cabling tester

- Electrical installation tester

- Resistance testing system

- Safety testing system

- Temperature sensor calibration bench

- Rugged testing system

- Process calibration bench

- Electrical safety testing system

- Handheld tester

- Calibration measuring machine

- Electrical equipment testing system

- LCR meter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.