Teledyne’s Model 1220 microprocessor-controlled gas detection system is specifically designed to monitor industrial locations such as refineries and chemical plants, and warn of the presence of potentially explosive gases and vapors.

In addition, the 1220 can activate ventilation or sprinkler systems or shut down process equipment until the danger is eliminated. Developed in collaboration with plant personnel who utilize gas detection equipment, the 1220 is a blend of flexibility and simplicity with state-of-the-art electronics.

Advantages

Dependable microprocessor based electronics

1MAN calibration

No field mounted electronics required

Rugged, field proven detectors

Building Block Concept

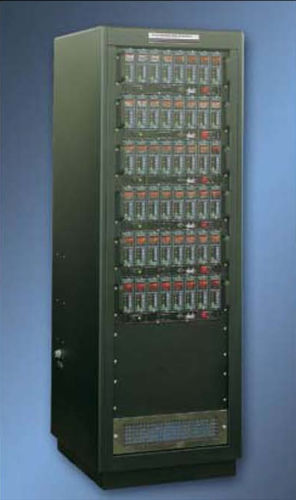

Virtually every application has unique requirements beginning with the number of locations to be monitored by one system. Therefore, flexibility is a key ingredient in the 1220’s design. A 1220 system is comprised of a central control station and remote detectors. A system can be as small or as large as needed because the control station incorporates a building block concept of control modules, each of which houses up to eight channel modules connected to one or two detectors mounted in the hazardous location.

A free standing system can accommodate up to seven control modules, 56 channel modules (figure 3) and 112 field mounted detectors. The detectors can be located well over a mile from the main system. Only AC or optional DC power is needed for the system to be fully operational.