- Hydraulics - Pneumatics

- Pump

- Syringe pump

- Teledyne Isco

- Products

- Catalogs

- News & Trends

- Exhibitions

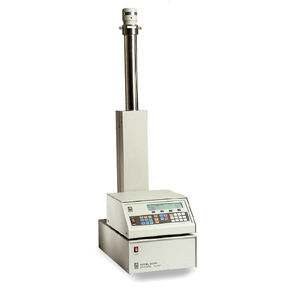

Syringe pump 260Dfor chemicalsstepper motor-drivenindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- syringe

- Fluid

- for chemicals

- Operation

- stepper motor-driven

- Domain

- industrial

- Applications

- filling

- Fluid specification

- for supercritical fluids

- Other characteristics

- rugged

- Flow

Min.: 0 m³/h

(0 ft³/h)Max.: 0.107 m³/h

(3.77867 ft³/h)- Pressure

Min.: 10 psi

Max.: 7,500 psi

Description

The 260D was the first ISCO D-Series pump module, and our first syringe pump designed specifically for refilling under high pressure and pressure programming to handle supercritical fluids. With pressure control to 517 bar (7,500 psi) and a flow rate range from sub-microliter to 107 mL/min, the 260D offers exceptional versatility for almost any type of R&D or method development with supercritical CO2 and other fluids. Dual-pump systems can provide the capability to meter solvent modifiers into the flow stream, or to deliver non-stop continuous flow.

The 260D is also used for a variety of other applications matching its flow and pressure specifications. For applications requiring pressures up to 10,000 psi and/or greater low-flow precision, see the 100D models.

Standard Features

260D pump has 1/8" Valco fittings for easy connection in process and pilot-plant plumbing.

Integral button-style pressure transducer in cylinder cap assures excellent stability and repeatability.

Rugged single-ratio drive train has auto-lubricating gears to assure long life and low maintenance.

Each ISCO D-Series syringe pump is bench tested at the factory.

Cylinder wash system protects the seals from deposits.

Exclusive "Smart Key" controller. All ISCO D-series pumps use the same controller that can operate any four pump modules, either independently or together. Operating modes include:

Single pump independent constant flow or pressure

Single pump flow - or pressure - ramp programming

Single pump dispensing

Dual pump continuous constant flow or pressure

Dual pump concentration gradients

Four-pump configured systems

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.