- Products

- Catalogs

- News & Trends

- Exhibitions

Liquid heater circulationelectriccompact

Add to favorites

Compare this product

Characteristics

- Treated product

- for liquids

- Type..

- circulation

- Heat source

- electric

- Other characteristics

- compact

Description

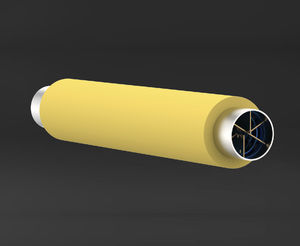

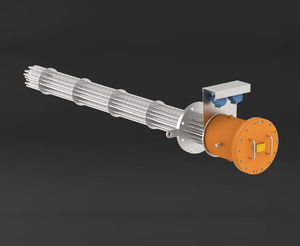

Circulation heater is a combined unit of Electric heater bundle inserted inside a Pressure vessel or shell, in which fluid will be flowing continuously. It is a compact heating system with fast heating of the process fluids.

The Circulation heaters are designed in such a way that cold process fluid enters the pressure vessel through inlet nozzle at a low temperature, passes though the active zone of the heater bundle and leaves the vessel through outlet nozzle at desired high temperature. The system is designed in such a way that heating element skin temperature and the pressure drop across the nozzles are maintained within permissible limits. The Circulation heater system can be designed in single stage vessel or multi stage vessels based on the process requirements. The System can be installed vertically or horizontally based on the requirement and space availability.

Technical Specifications

Rating From 1kW to 5000kW (Max) in Single Bundle or combination

Design Temperature -40 deg C to 650 degree C

Design Pressure Up to 350 bar(g)

Pressure Vessel LTCS/ CS / SS, Alloy steel

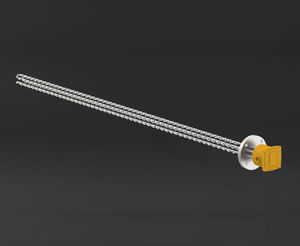

Heating Element Mineral filled insulated Heating Elements or Tubular heating Elements with

Ni-Cr (80-20) as heating Coil and suitable outer sheaths

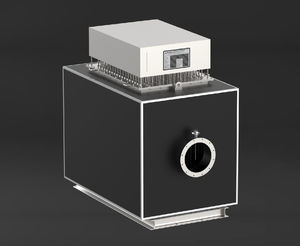

Control System Thyristor control Panel + Local control Stations for effective temperature

control & safe operation. ( Safe area or Hazardous area)

Catalogs

No catalogs are available for this product.

See all of TEMPSENS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.