- Products

- Catalogs

- News & Trends

- Exhibitions

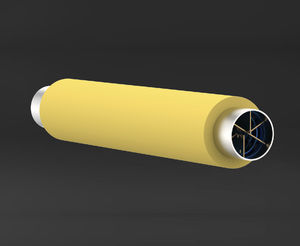

Mineral-insulated heating cable

Add to favorites

Compare this product

Characteristics

- Sheathing / insulating material

- mineral-insulated

Description

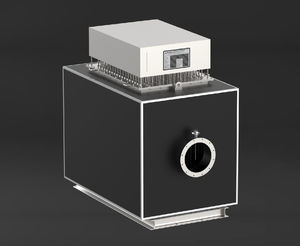

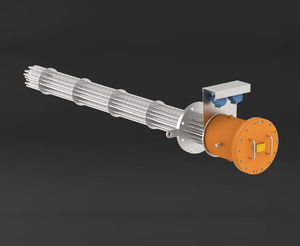

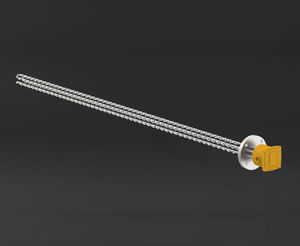

Mineral insulated heating cables provide rugged, high temperature and reliable heat tracing for different customize applications. MI cables constructed by high nickel alloy sheath materials, magnesium oxide dielectric insulation and resistance wire construction allow the tracing of surface up to 600°C maintain temperatures and excellent resistance to harsh & many corrosive environments. MI heating cables and heater units are widely used in areas where high temperature, high pressure, high radiation, or corrosive environments exist, and where high power density field, and electric heating or heating processes exist.

Technical Specifications

Voltage Up to 600V

Cold Resistance Tolerance ≤3%

Heating Element Ferritic Alloys- Powder metallurgical element, Mara FeCrAl, NiCr 80/20

Temperature Range Up to 600°C

Sheath Materials Nickel Alloys 600/ 825, Stainless steel Alloys SS304, SS316, SS321

Heating Parameters Customized - Power rating, voltage, resistance, length, diameter and other dimensions

Catalogs

No catalogs are available for this product.

See all of TEMPSENS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.