- Products

- Catalogs

- News & Trends

- Exhibitions

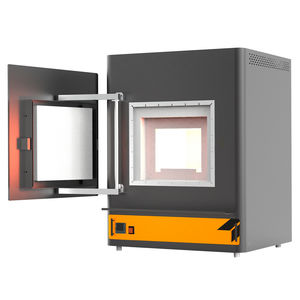

Chamber furnace BLFsinteringcalcinationhigh-temperature

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- sintering, calcination

- Other characteristics

- high-temperature

- Maximum temperature

1,200 °C, 1,400 °C, 1,600 °C, 1,800 °C

(2,192 °F, 2,552 °F, 2,912 °F, 3,272 °F)

Description

Bottom loading furnaces are designed for uniform thermal distribution inside the chamber, easy loading and unloading of the sample with help of lifting arrangement. Bottom loading furnaces are ideal to achieve a variety of heating-cooling cycles without sacrificing temperature uniformity or product quality. These furnaces are well suited for calcining, firing and sintering oxide ceramic parts (i.e., alumina, zirconia), technical ceramics, co-fired substrate materials, capacitors, filters, thermistors, ferrites.

Thehigh-temperaturebottomloadingfurnacesareadditionally equipped with a drying as well as a forced cooling function. For residual drying, the oven remains open gapwise during heating up to a defined temperature and thus ensures reliable removal of moisture. For accelerated cooling, the furnace is automatically opened step by step under program control.

Maximum Operating Temperature

1200/1400/1600/1800°C

Heating Element

Kanthal A1/Silicon Carbide/MoSi2

Temperature Controller

Microprocessor based PID controller

Bottom Lifting Arrangement

Bottom lifting plate fitted with DC motor ensure smooth lifting & lowering.

Catalogs

No catalogs are available for this product.

See all of TEMPSENS‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Vacuum furnace

- Annealing furnace

- Thermal furnace

- Horizontal furnace

- Sintering furnace

- Conveyor furnace

- Tempering furnace

- Muffle furnace

- Inert gas furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.