- Industrial machines and equipment

- Mixing and Dosing

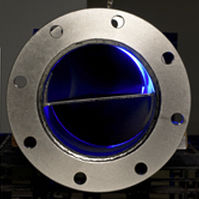

- Dynamic mixer

- Teralba Industries Pty Ltd

Dynamic agitator Mixquip®batchsolidstainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- batch

- Product type

- solid

- Other characteristics

- stainless steel

- Applications

- for the food industry

Description

The Mixquip® top entry agitator mixers incorporate advanced designs in mixing technology. These state-of-the-art series achieve ultimate blending/mixing conditions in open or closed top vessels. Blending liquids and powders, maintaining solids in suspension, ph correction and aerating products plus many other duties which are achievable by drawing on know-how and unique impellor designs.

Electric drives spanning from 40Kw units down to fractional horsepower illustrate the range of top entry agitators designed and manufactured in Australia.

Custom built ability encompasses exotic metals such as Titanium, Stainless Steel and Super Duplex alloys. Ideal for mixing corrosive or high temperature products.

Operating Principle:

The Mixquip® top entry agitator is positioned at the top of the mixing vessel to achieve controlled, uniform flow patterns ensuring the vessel contents are kept in motion for the desired mixing conditions.

Features:

- Versatile - The Mixquip® top entry agitators are designed for fixed in-tank installation and can be attached to an integral mounting on the vessel or suspended from a support structure.

- Low Maintenance - The Mixquip® agitators are designed to minimize maintenance. The top-entering shaft ensures that no mechanical seals are required to retain tank contents.

- Propellers - The Mixquip® propeller designs are carefully selected to provide optimum process conditions. Each design incorporates advanced technology to provide effective liquid movement.

- Adaptive - Shafts can be provided for most tank heights, with support provided by bearing housings with in-tank foot bearings if required.

Other Teralba Industries Pty Ltd products

Mixing and Agitating Solutions

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Horizontal blender

- Homogenizer for the cosmetics industry

- Compact agitator

- Laboratory homogenizer

- Ribbon blender

- Water treatment agitator

- Static mixer

- Emulsifier

- High-pressure homogenizer

- Side-mount agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.