- Industrial machines and equipment

- Mixing and Dosing

- Emulsifier

- Teralba Industries Pty Ltd

Emulsifier

Add to favorites

Compare this product

Description

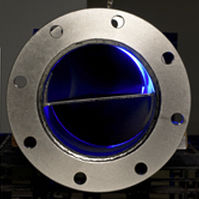

Mixquip® Emulsifiers or homogeneous pumps are a high-efficiency product integrating emulsion, dissolution, refinery, disaggregation, homogenization, and emulsification. The main parts are stators and rotors. Emulsifiers are very effective in applications where a high shear is required. Thorough and efficient emulsification is achieved by a rapid mechanical and hydraulic shear of ingredients, high-speed rotation as well as centrifugal force through a perforated screen. The repeat of this process can result in stable and high-quality products.

The mixing cycle is divided into three stages, the first being when the materials are drawn into the mixing chamber and subjected to intense mixing in the chamber by the high-speed rotor. The second stage occurs when the materials are expelled through the perforated screen and subjected to intense shear at extremely high velocity by the rotor blades. The third stage is the expulsion of the processed ingredients with great force and velocity into the body of the mix or into the recycling vessel.

Suitable for free flowing liquids, food, chemicals, cosmetics, pharmaceuticals, creams, fruit juices, semi-solids, waxes etc.

Features:

- All wetted parts are 316 grade Stainless Steel.

- External seal for sanitary operation.

- Quick opening for easy cleaning.

- Hygienic design.

- Australian design and manufacture.

Catalogs

No catalogs are available for this product.

See all of Teralba Industries Pty Ltd‘s catalogsOther Teralba Industries Pty Ltd products

Mixing and Agitating Solutions

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Horizontal blender

- Homogenizer for the cosmetics industry

- Compact agitator

- Laboratory homogenizer

- Ribbon blender

- Water treatment agitator

- Static mixer

- Emulsifier

- High-pressure homogenizer

- Side-mount agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.