- Industrial machines and equipment

- Mixing and Dosing

- Ribbon mixer

- Teralba Industries Pty Ltd

Ribbon blender batchfor liquidsvertical

Add to favorites

Compare this product

Characteristics

- Technology

- ribbon

- Batch/continuous

- batch

- Product type

- for liquids

- Configuration

- vertical, horizontal

- Applications

- for the food industry, for the cosmetics industry

Description

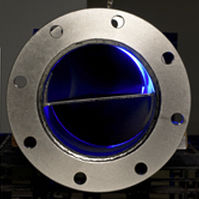

Mixquip® ribbon blenders generally consist of some type of closed container, usually with a shape similar to a feed trough. The shaft, with attached blades, is located inside the container. The blades of the ribbon blender look like two metal ribbons winding around the shaft, in a double helix design. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 92 mpm, moving materials both radially and laterally to ensure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender. It ensures mixing that reaches each and every corner of the trough and imparts radial and linear motion to the whole material/liquid that is being mixed.

The ribbon mixer can have a horizontal construction, where the shaft and blade are sideways in the container, or the shaft and blade can be in a vertical position.

Ribbon blenders are usually used when one of the items being mixed has a higher percentage of particles content, and it's important that all of the ingredients are mixed evenly. It can be used for food or medicine manufacturing as well as other heavy industry applications. The shape of the ribbon blender also ensures that no ingredients are left undisturbed on the bottom of the container, and that all portions of the mixture are blended evenly with the same ratio of ingredients.

Catalogs

No catalogs are available for this product.

See all of Teralba Industries Pty Ltd‘s catalogsOther Teralba Industries Pty Ltd products

Mixing and Agitating Solutions

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Horizontal blender

- Homogenizer for the cosmetics industry

- Compact agitator

- Laboratory homogenizer

- Ribbon blender

- Water treatment agitator

- Static mixer

- Emulsifier

- High-pressure homogenizer

- Side-mount agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.