- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Gas pipe 804 seriesfor mineral oilfor airfor compressed air

Add to favorites

Compare this product

Characteristics

- Use

- for gas, for compressed air, for air, for mineral oil

- Material

- aluminum

- Applications

- transport, cooling, for vacuum, dispensing

- Norms

- DIN

- Other characteristics

- fire-resistant, smooth, lightweight, extruded, square, curved, with smooth inner surface, UV-resistant, oil-resistant, T, custom, quick-connect, modular, elbow, rugged, silicone-free, other fluid

- Inner diameter

11 mm, 15 mm, 22 mm, 30 mm

(0.433 in, 0.591 in, 0.866 in, 1.181 in)- Outer diameter

20 mm, 25 mm, 40 mm, 50 mm, 63 mm

(0.787 in, 0.984 in, 1.575 in, 1.969 in, 2.48 in)- Pressure

Min.: 0 bar

(0 psi)Max.: 25 bar

(362.594 psi)- Temperature

Min.: -20 °C

(-4 °F)Max.: 120 °C

(248 °F)- Delivered length

2.5 m, 5 m

(8'02" , 16'04" )

Description

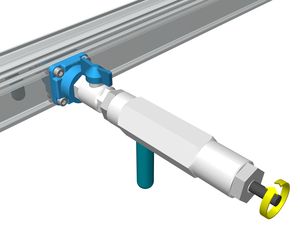

The patented AP system is suitable for inert gases and fluids.

By doubling the clamping brackets of every single joint and terminal of the system, the product can be used at a working pressure of up to 25 bar (360 psi).

The increase of the working pressure enables the transportation of incompressible fluids, such as mineral and synthetic oil, cooling and lubricating fluids.

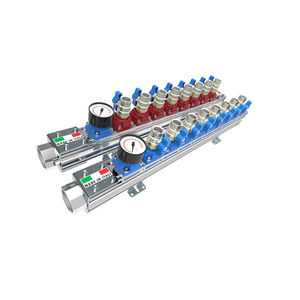

For such a specific application a series of dedicated accessories are available, such as safety relief valves, manometers and expansion tanks, illustrated in the following pages.

Kiwa has determined that the quality management system of Teseo Srl meets the requirements of Annex III, E1 of the Pressure Equipment Directive 2014/68/UE.

KIWA Certificate n°: R09351RM-01. Marking CE0476.

The following advantages stand out

-Easy and quick to assemble, no special tools required, it can be assembled without special skills.

-Its simple section is symmetric and can be used on all the sides. Easy to cut and bend.

-Equipped with numerous accessories which are designed of simple modular elements -compatible both with the present HBS system and steel pipes with “Gas” BSP or NPT threads.

-A very competitive price, thanks to the quick mounting, AP is more convenient than a traditional piping system.

TECHNICAL CHARACTERISTICS

-Extruded Aluminium: Alloy EN AW 6060 UNI EN 573-3:1996

-International designations: ANSI 6060 - DIN 1748/1: AlmNsl 0,5 BS 6060

-Chemical composition: Si: 0,45% - Mg: 0,45% - Fe: 0,3%

-Heat treatment: Aging T5 o T6

-Surface treatment (upon request) : Chemical silver anodization

-Specific weight, density: Kg/dm3 2,71

Catalogs

Other TESEO products

ALUMINIUM FLUID DISTRIBUTION SYSTEMS - BAR, PIPEWORKS AND ACCESORIES

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.