- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

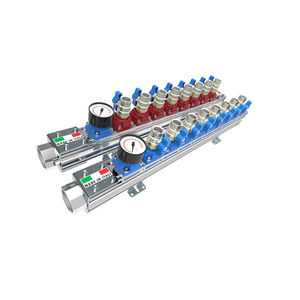

Compressed air pipe HBS seriesfor gasfor nitrogenaluminum

Add to favorites

Compare this product

Characteristics

- Use

- for gas, for compressed air, for nitrogen

- Material

- aluminum

- Applications

- for compressed air networks

- Norms

- DIN

- Other characteristics

- extruded, with smooth inner surface, modular, rectangular

- Inner diameter

Min.: 18 mm

(0.709 in)Max.: 115 mm

(4.528 in)- Outer diameter

Min.: 25 mm

(0.984 in)Max.: 110 mm

(4.331 in)- Pressure

15 bar

(217.557 psi)- Temperature

Min.: -20 °C

(-4 °F)Max.: 120 °C

(248 °F)

Description

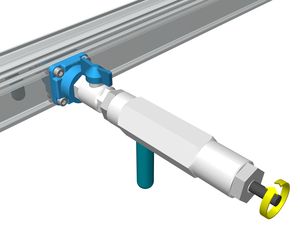

The great innovation of this unique system lies in the methods and means to add lines of compressed air and other fluids under pressure. The system is mainly composed of an extruded aluminium bar, which presents an external rectangular section with tee slots and an internal bore of large dimension to carry a considerable flow of compressed air.

A wide selection of straight joints, T or L joints allows for airlines of whatever length and shape. To complete the equipment we supply a number of outlet plates of various dimensions and shapes. The Teseo Modular aluminium Pipework System is leak free due to positive o-ring seals.

The following advantages stand out

-Fast installation.

-Quick installation of additional outlets.

-Easy to make changes and add new branch lines.

-Clean and smooth inner and outer surfaces.

-Integrated modular system

TECHNICAL CHARACTERISTICS

-Extruded Aluminium: Alloy EN AW-6060 UNI EN 573-3:1996

-International designations: ANSI 6060 - DIN1748/1: AlMgSi 0,5 BS 6060

-Chemical composition: Si: 0,45 - Mg: 0,45 - Fe: 0,3

-Heat treatment: Aging T5 o T6

-Surface treatment (upon request) : Chemical silver anodization

-Specific weight, density: Kg/dm³ 2,71

-Electrical conductivity: % IACS 53

-Thermal Conductivity: W/m·K 200

-Specific heat: J/Kg·K 96

-Chaleur spécifique: J/Kg·K 96

Coefficient de dilatation: mm/m °C 0,024

-Charge max. de traction: Kg/mm² 24

-Charge de rupture: Kg/mm² 20

-Module d’élasticité: Kg/mm² 6.700

-Yield strength: Kg/mm² 20

-Modulus of elasticity: Kg/mm² 6.700

-Brinell hardness: HB 70÷80

-Melting range: °C 600-650

-O-ring material: NBR 70

-Screw material : Steel class 8.8

-Screw driving torque: Nm 10÷13,5 (90÷120 Inch Lbs)

Catalogs

BROCHURE

4 Pages

Other TESEO products

ALUMINIUM FLUID DISTRIBUTION SYSTEMS - BAR, PIPEWORKS AND ACCESORIES

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.