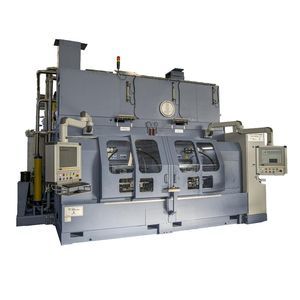

Multi-parameter test stand 1027automaticfor mechanical drivefor the automotive industry

Add to favorites

Compare this product

Characteristics

- Test type

- multi-parameter

- Operating mode

- automatic

- Test material

- for mechanical drive

- Sector

- for the automotive industry, agricultural

Description

Example of production test bench for agricultural transmissions. The tests are performed according to the customer testing procedures that set the parameters to be investigated and the relative acceptance ranges. These machines can be simpler or more complex depending on the customer’s requirements.

All units are controlled by a PC and acquisition system, with proprietary software for the writing and setting of parameters, archiving and printing of the results, as well as for machine management.

If required, it is possible to perform NVH analysis and CANbus communication with ECU and TCU management.

TESTS PERFORMED

• Flushing

• Running-in

• Gearbox functionality

• Differential lock functionality

• 4WD functionality

• Lift functionality

• PTO functionality

• Auxiliary valve functionality

• Solenoid valve leakage

• Clutch slippage

• Proportional valve linearity (graphic test)

• Lubrication check

• Power loss check

• Electrical and electronic device check

• Hydraulic valve settings check

• External leaks check

Catalogs

No catalogs are available for this product.

See all of Test Industry‘s catalogsRelated Searches

- Test machine

- Measuring machine

- Test stand

- Automatic test machine

- Vertical test machine

- Automatic test stand

- Industrial test machine

- Precision test machine

- Research and development test machine

- Electromechanical test machine

- Optical measuring machine

- Automatic measuring machine

- Pressure test stand

- Test machine for the automotive industry

- Fatigue test machine

- Industrial test bench

- Resistance test machine

- PC-controllable test bench

- Test set

- Mechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.