- Products

- Vertical cheese press

- Tetra Pak

- Products

- Catalogs

- News & Trends

- Exhibitions

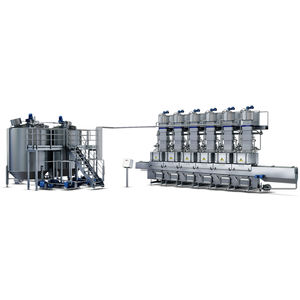

Vertical cheese press system 6pneumaticstainless steel

Add to favorites

Compare this product

Characteristics

- Orientation

- vertical

- Operation

- pneumatic

- Other characteristics

- stainless steel

Description

Tetra Pak® Blockformer system 6 is a customised, prefabricated and validated blockforming solution, including all the engineering, piping, valves etc. for cheddar cheese. Our solutions are backed by long-term technical support, as well as by written performance guarantees. The Tetra Pak Blockformer system 6 solution offers:

• Excellent, uniform product quality

• Proven high capacity

• High and consistent weight accuracy

• Minimal product losses

• Robust, durable construction

• Simplified, reliable operation

• Open, easy-to-clean design

• Low maintenance cost

• Reduced environmental impact

When consistent results count

• Creates cheese blocks of a uniform size and weight

• Low losses thanks to features like the double action door, interceptor plate and angled ejector block.

• Food safety is embedded throughout the design, including folded stainless-steel base unit

Features

Accurate weight control

A pneumatic drive keeps weight deviations down to a minimum. For accuracy’s sake, the desired cutting height is reached in very small steps – less than a gramme at a time. Having set the maximum block weight, the drive automatically corrects production parameters if the weight exceeds this upper limit.

Reduces maintenance needs and product losses

When the tower has been filled with product, air flows through the system and moves it along. A built-in interceptor plate prevents small particles from being removed along with the air. This is placed at a slight angle in the tower, capturing fines (curd particles) from the airflow, and reducing losses by up to 50%

VIDEO

Catalogs

Tetra-laval-2017-2018

60 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.