- Products

- Catalogs

- News & Trends

- Exhibitions

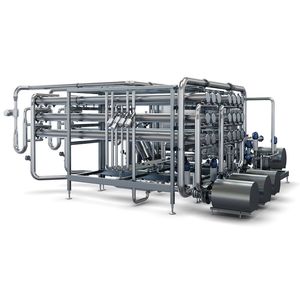

Industrial food processor V seriesmultipurposefor viscous products

Add to favorites

Compare this product

Characteristics

- Options

- industrial, multipurpose, for viscous products

Description

The Tetra Pak® Food Processor achieves efficient processing of low to high viscous and smooth to particulate products. It comes in two different models; Tetra Pak Food Processor V series and Tetra Pak Food Processor with a horizontal helix agitator.

Capacity

• Tetra Pak Food Processor V series: vessel size from 250 to 6,000 litres

• Tetra Pak Food Processor with a horizontal helix agitator: vessel size from 300 to 2,500 litres

Applications

Ready meals, soups, broths, fruit preparations, jams and marmalades, traditional and international dishes, sauces and pastes, confectionery

Produce consistent, authentic recipes every time

• Suitable for batch production or product pre-treatment in a continuous line

• Ingredients quality maintained thanks to gentle treatment

• One machine to thaw, blend, deaerate, evaporate and cool product

Features

Like a chef’s spoon

The agitator’s counter-rotating double shafts reach all vessel areas to create a homogenous blend regardless of viscosity. A dynamic stator system and variable shear handle sensitive particles and ensure even particle distribution.

Controls aroma loss and maximizes taste

The closed vessel setup gives the possibility to control steam evaporation and thus regulate the recipe and its taste. The closed vessel also recovers aromas that evaporate with the steam. These can be added back into the product or retained for use in other foods.

Regulates all key parameters

Auto chef is the intuitive automation brain at the heart of the food processor. Based on the Tetra Pak® PlantMaster automation system and the product, it provides complete recipe management and can store up to 800 recipes.

VIDEO

Catalogs

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Drying system

- Homogenizer for the food industry

- In-line dryer

- In-line mixer

- Tipping station

- Drying system for the food industry

- Homogenizer

- Upright freezer

- Dynamic homogenizer

- Pasteurizer

- Heat sterilizer

- Pasteurizer for the food industry

- Process sterilizer

- Air drying system

- Batch homogenizer

- Homogenizer for the food industry

- Automatic pasteurizer

- Cooling freezer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.