- Products

- Catalogs

- News & Trends

- Exhibitions

Fruit juice pasteurizer BFfor dairy productstomato pasteautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- fruit juice, for dairy products, tomato paste

- Operating mode

- automatic, tubular, continuous

- Other characteristics

- plate heat exchanger, for high temperatures

- Liquid pasteurizer capacity

Max.: 55,000 l/h

(14,529.46 us gal/h)Min.: 3,000 l/h

(792.52 us gal/h)

Description

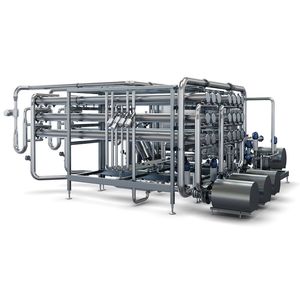

Tetra Pak® Pasteurizer BF is a processing unit for highly efficient, continuous temperature treatment of beverage products. The unit is of aseptic or hot-fill design and uses a tubular or plate heat exchanger for indirect heating to obtain a product that can be stored at ambient temperatures.

Tetra Pak Pasteurizer BF is suitable for beverage products such as juices, nectars, still drinks or juice drinks, isotonic beverages, tomato juice, smoothies, energy drinks, milk-juice beverages, and sensitive carbonated soft drinks with or without fibres and particles.

Tetra Pak Pasteurizer BF is available as a standalone unit or as part of a complete line solution.

Quick facts

A premium pasteurization unit with unsurpassed flexibility. Low cost of ownership, flexible and future-proof while ensuring food safety.

Capacity

The Tetra Pak Pasteurizer BF is available with variable capacity and can run capacities from 3 000 l/h up to 55 000 l/h.

Applications

Juices, nectars, still drinks or juice drinks, isotonic beverages, tomato juice, smoothies, energy drinks, milk-juice beverages, and sensitive carbonated soft drinks with or without fibres and particles.

Premium pasteurizer with unsurpassed flexibility

• Low total cost of ownership

• Flexible and future-proof while ensuring food safety

• Faster time to market

Features

Ensures food safety

Booster pumps create a differential pressure between the pasteurized and unpasteurized side of the unit. To further enhance safety, this differential can be monitored by pressure transmitters.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tetra Pak‘s catalogsRelated Searches

- Drying system

- In-line dryer

- Drying system for the food industry

- Pasteurizer

- Heat sterilizer

- Pasteurizer for the food industry

- Process sterilizer

- Concentrator

- Air drying system

- Automatic pasteurizer

- Sterilizer for the food industry

- Dairy product pasteurizer

- Spray drying system

- Modular drying system

- Concentrator for the food industry

- Fruit juice pasteurizer

- Nozzle dryer

- UHT sterilizer

- Tubular pasteurizer

- Conical bottom dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.