- Products

- Catalogs

- News & Trends

- Exhibitions

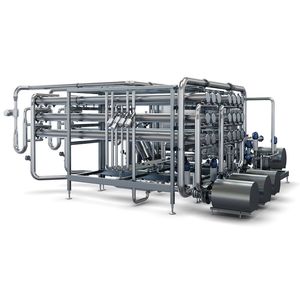

CIP unit for the food industry P

Add to favorites

Compare this product

Characteristics

- Options

- for the food industry

Description

Tetra Pak® CIP unit P is an advanced automatic cleaning-in-place system used for cleaning process equipment such as filling machines, pasteurisers, sanitary pipes, tanks, aseptic tanks, plate heat exchangers etc.

Capacity

6 – 50,000litres/hr and 1- 4 pressure lines

Applications

Dairy, beverages and food

Smart CIP safety

Simple and modular – easy to install and use with premium performance

Cost effective – enable economical use of water and detergents

Flexible – adapt cleaning programs or create your own to meet specific production needs

Features

Prevents detergent waste and saves time

Tetra Pak® CIP unit P creates a virtual image of each cleaning circuit. This, combined with a liquid tracking system, keeps track of the different cleaning phases. The unit 'knows' when the mix of detergent and water reaches the part of the machine where it should be separated into its different parts again. Knowing where all the liquids are enables accurate recovery to the right tank. This minimizes the dilution of stored detergent, as well as reducing waste (i.e. flushing detergent down the drain).

Minimises water consumption and saves time

The CIP unit's automation system enables full control of all the liquid in the cleaning circuit. The 3 standard cleaning phases are caustic, water (which flushes out the caustic) then acid. Liquid tracking makes it possible to separate the caustic and acid phases with a water plug instead of a full rinse. This minimises water consumption and reducing waiting time before starting the acid phase.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.