- Products

- Catalogs

- News & Trends

- Exhibitions

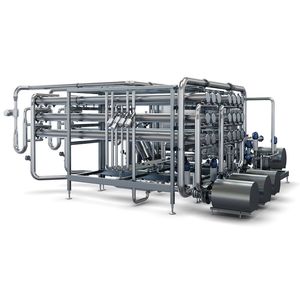

Clarifier BrineClear™

Add to favorites

Compare this product

Description

Feta and similar cheese types are manufactured by full сoncentration of the milk using UF. Culture or acid, rennet, salt and other additives are added to the retentate, and it can then be cast straight into the appropriate packaging.

Fresh cheese types based on fermented milk or cream, such as quark or cream cheese, can also be manufactured using UF. After fermentation, the product is concentrated to the desired level followed by final treatment and packaging. The UF process results in a high, uniform quality and a very high yield. At the same time it is possible to manufacture several different products on the same UF plant.

High-quality cheese with clean brine

Microfiltration removes impurities and harmful microorganisms from the cheese brine swiftly and efficiently, while preserving the natural chemical balance of the brine. We have developed the special BrineClear™ concept, which has proved to be a supremely good solution, technically as well as financially

Cheese brine clarification

Good quality brine is essential to cheese flavour, taste, rind, and appearance of the cheese. Poor brine, however, is a significant threat to the cheese quality and can lead to spoilage of the cheese and economic loss.

Over time, microorganisms such as bacteria, spores, yeast, and mould will build up in the brine and be transferred to the cheese during the salting process. Eventually, heavily contaminated brine can lead to surface contamination of the cheese and degrade the cheese quality.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.