- Products

- Catalogs

- News & Trends

- Exhibitions

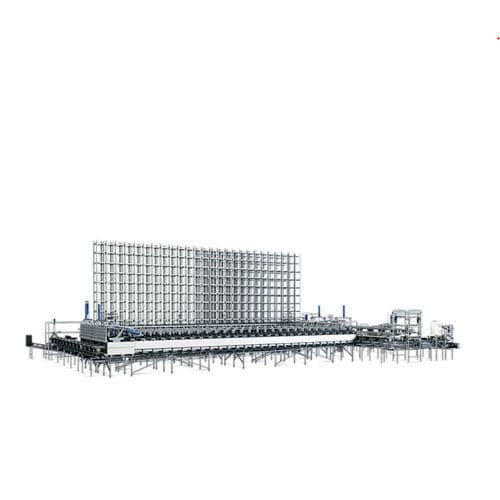

Automated materials handling system high-speedflexiblecheese

Add to favorites

Compare this product

Characteristics

- Operating mode

- automated, flexible, high-speed

- Product applications

- handling, cheese, for cheese molds

- Applications

- for food applications

Description

The Tetra Pak® Mould Handling system is an advanced solution used for pressing and forming of semi-hard and hard cheeses in closed presses with complete mould and lid handling.

Working principle

The curd blocks, leaving the draining forming equipment, are collected in a mould. After the mould is covered with a lid by the lid placer the moulds are conveyed to the final pressing section in closed execution where the curd block is pressed to shape the cheese, and to form a uniform rind around the cheese by a gradually increasing pressing force. Downstream in the final pressing section the cheeses are de-moulded in the de-moulding line and conveyed to a brining system. The moulds and lids are turned upside down before they are cleaned by the rinsing machine and are ready to be re-used again.

The Tetra Pak Mould Handling system is PLC controlled. The closed final presses are cleaned in place.

Highlights

• Hygienic design

• Fully automated and controlled production process

• Flexibility to press cheeses of different shapes and sizes on the same equipment

Capacity:

Up to 100 tonnes/day

Applications:

Semi-hard cheese

Speed and flexibility

• Flexibility to press cheeses of different shapes and sizes on the same equipment

• Hygienic production environment - consistently high-quality product

• Maximum uptime, thanks to shorter cleaning cycles

Features

Easy switch

Flexible Mould Handling systems are available if you want to produce cheeses of different shapes. The mould handling including the Laude moulds areas designed in such a way to handle different mould types in one Mould Handling system.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tetra Pak‘s catalogsRelated Searches

- Tipping station

- Automated materials handling system

- Tipping station for the food industry

- Manual tipping station

- Stainless steel tipping station

- Handling materials handling system

- Automatic tipping station

- Compact tipping station

- Flexible materials handling system

- Materials handling system for food applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.