- Products

- Catalogs

- News & Trends

- Exhibitions

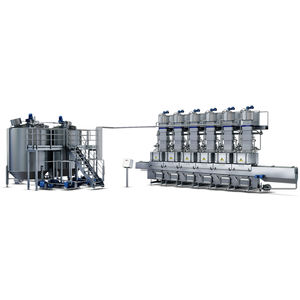

Cheddar cheese production machine 5automatic

Add to favorites

Compare this product

Characteristics

- Cheese type

- cheddar

- Operational mode

- automatic

Description

The Tetra Pak® Cheddaring 5 machine is designed for continuous production of fused and stirred Cheddar and pasta filata cheese types. It is a totally enclosed machine, designed to automatically drain, acidify, texture, mill, salt and mellow cheese curd.

Advantages:

• Totally closed environment

• Drainage, fusing/stirring and salting in one machine

• Efficient whey drainage system

• Plastic USDA approved conveyor

• Flexibility of cheese types

• Space saving

• Complete sweet and salt whey separation with unique whey sump design

• Most accurate salting system

Capacity ranges from 1,000 – 16,000 kg/hr.

High-capacity, consistent cheddar production

• Every detail of the design - from inlet screen to mellowing - is optimized to give a consistent end product

• Smart features such as the perforated draining belt and whey screen design ensure a high yield with minimal curd losses

• Hygiene is secured by e.g. pyramid shaped sumps and strategically located cleaning devices

Features

Effective whey drainage

There are 9 litres of whey for every litre of curd. Made of stainless steel wedge wire, the inlet screen has gaps of just 0.25 mm between each wedge. This means a high proportion of the liquid can drain through the holes, but very few curd particles pass through.

Catches the curd particles, maximizing yield

Any rogue curd particles that have not been caught by the first inlet screen, are caught in this, the second whey screen. All the whey that passes through the screen is immediately collected before it has had time to accumulate bacteria – so it can be categorized as ‘high-quality whey’.

Catalogs

Related Searches

- Homogenizer

- Dynamic homogenizer

- Pasteurizer

- Heat sterilizer

- Pasteurizer for the food industry

- Process sterilizer

- Batch homogenizer

- Homogenizer for the food industry

- Automatic pasteurizer

- Sterilizer for the food industry

- Liquid homogenizer

- Dairy product pasteurizer

- Cheese vat

- Fruit juice pasteurizer

- Cheese production machine

- Stainless steel cheese vat

- Milk separator

- Dairy product homogenizer

- High-pressure homogenizer

- Cheese brining system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.