- Products

- Catalogs

- News & Trends

- Exhibitions

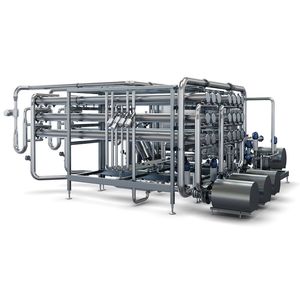

Sugar dissolver continuous

Add to favorites

Compare this product

Characteristics

- Options

- sugar, continuous

Description

The Tetra Pak® Continuous Sugar Dissolver continuously dissolves crystalline sugar in water up to a concentration of 65°Brix with output capacities of 7,000, 15,000 and 25,000 litres per hour – for use in the production of still drinks, carbonated beverages, ketchup, jam, confectionary products, formulated dairy products and more

The hydraulic conveying solution minimizes your investment and operational costs and lets you place your sugar dissolver more flexibly in your plant layout. On top of that, our patented injector technology and efficient radial jet mixer enable lower dissolving temperatures, letting you reduce energy consumption and costs by 25%. And you get guaranteed Brix accuracy, for exact dosing, while securing long-term sustainability.

Smart, flexible solution with hydraulic conveying

• Minimize investment and operational costs with smart hydraulic sugar conveying solution

• Flexibly place your sugar dissolver for more flexible plant layout

• Reduce energy consumption and cost by 25% with lower dissolving temperature

• Get guaranteed °Brix accuracy for exact dosing

Features

Minimizes energy consumption

Our patented injector system enables hydraulic conveying but it also reduces energy consumption overall. Due to the immediate wetting of sugar and the high turbulence as soon as the sugar touches the water stream.

Once the sugar has passed the injection point, it is conveyed hydraulically to a radial jet mixer, which provides enough turbulence inside the dissolving tank to keep the sugar crystals in abeyance and dissolve them efficiently. This allows us to lower the dissolving temperature and, thus, the energy consumption.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tetra Pak‘s catalogsRelated Searches

- Dynamic homogenizer

- Batch homogenizer

- Drying system

- Homogenizer for the food industry

- In-line dryer

- In-line mixer

- Tipping station

- Drying system for the food industry

- Homogenizer

- Upright freezer

- Dynamic homogenizer

- Pasteurizer

- Heat sterilizer

- Pasteurizer for the food industry

- Process sterilizer

- Air drying system

- Batch homogenizer

- Homogenizer for the food industry

- Automatic pasteurizer

- Cooling freezer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.