- Products

- Catalogs

- News & Trends

- Exhibitions

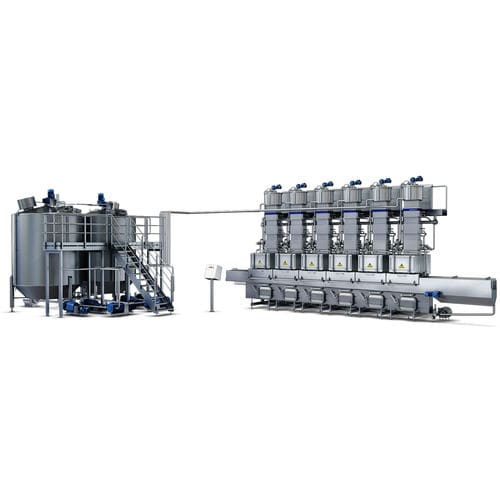

Hard cheese production line SC7automatic

Add to favorites

Compare this product

Characteristics

- Cheese type

- hard cheese

- Operational mode

- automatic

Description

The Tetra Pak® Casomatic system SC7 module enables you to produce cheese and whey of higher quality more efficiently than ever before. Tetra Pak Casomatic system SC7 provides a fully automatic and continuous system for whey drainage, pre-pressing, accurate cheese block formation and mould filling in one sequence.

Tetra Pak Casomatic system SC7 is suitable for the production of hard and semi-hard cheese types but by adding a de-wheying screen, granular types of cheese can also be produced.

The high capacity per column is reached by the application of a flexible whey drainage system. When producing a single cheese size Tetra Pak Casomatic system SC7 is the system to choose.

Tetra Pak Casomatic system SC7 offers the following advantages:

• Efficient solution

• Long production runs

• Reliable performance

• Excellent whey quality

• Accurate moisture content

• Outstanding weight accuracy

• Good cheese quality

• Improved environmental performance

Efficient, effective medium to high volume cheese production

• High-quality cheese and whey production thanks to the gentle treatment of cheese and his self-cleaning functionality

• Maximum yield, with tightly controlled process that eliminates weight and moisture variations

• Certified machinery with hygienic operation enhances food safety, and enables shorter cleaning cycles

Features

Reduces variations in moisture content

A dimple jacket is wrapped around the conical part of the buffer tank, cooling the curd/whey mixture during filling, residence and emptying.

VIDEO

Catalogs

Moving Food Forward. Together?

24 Pages

Related Searches

- Homogenizer

- Dynamic homogenizer

- Pasteurizer

- Heat sterilizer

- Pasteurizer for the food industry

- Process sterilizer

- Batch homogenizer

- Homogenizer for the food industry

- Automatic pasteurizer

- Sterilizer for the food industry

- Liquid homogenizer

- Dairy product pasteurizer

- Cheese vat

- Fruit juice pasteurizer

- Cheese production machine

- Stainless steel cheese vat

- Milk separator

- Dairy product homogenizer

- High-pressure homogenizer

- Cheese brining system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.