The H-Cube® Mini Plus is a safe, powerful and affordable flow reactor which generates high-pressure hydrogen gas on-demand with the electrolysis of water, allowing chemists to perform catalytic hydrogenation reactions from atmospheric pressure and room temperature to 100 bar and 100 °C in minutes.

Hydrogenation is one of the most important reactions in chemical synthesis, but the hazardous nature of hydrogen limits its use. The H-Cube® series have already eliminated the dangers associated with hydrogenation through the use of in situ hydrogen generation and the handling of pyrophoric catalysts by filling them in sealed catalyst cartridges (CatCarts®). This technology has been adopted by the leaders in the pharmaceutical, flavor and fragrance, fine chemical, agrochemical industries and in academia.

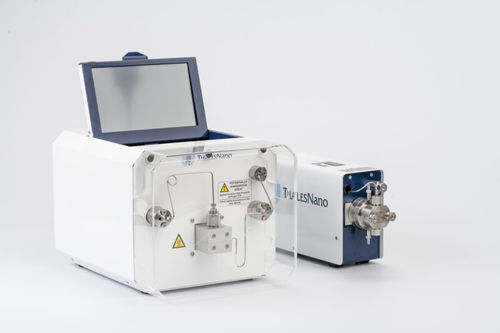

Features of the H-Cube® Mini Plus

• Hydrogenation without cylinders

• No catalyst filtration

• Fast reactions

• Easy-to-use

• Affordable

• Built-in video tutorial

• Automated hydrogen drying system

How does the H-Cube® Mini Plus work?

• The hydrogen is generated by the electrolysis of water inside the system.

• The HPLC pump introduces the pure solvent into the system, where it is mixed using a mixing valve with the hydrogen.

• The gas-liquid mixture passes through the reaction zone while the system prepares to work at the selected parameters (pressure, temperature and flow rate).

• When the desired parameters are achieved, the user can change the input from the solvent to the solution of the reactants.

• The reaction mixture passes through a packed column containing the solid catalyst (CatCart®), where the reaction takes place.