- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

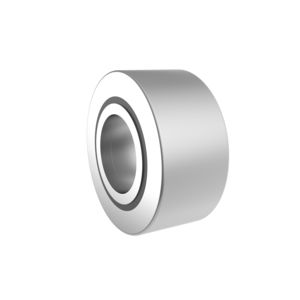

Crossed roller bearing SX 011818axialsteelfor gear reducers

Add to favorites

Compare this product

Characteristics

- Rolling element

- crossed roller

- Configuration

- axial

- Material

- steel

- Applications

- for gear reducers, turntable

- Other characteristics

- high-precision

- Inside diameter

90 mm

(3.54 in)- Outside diameter

115 mm

(4.53 in)- Width

13 mm

(0.512 in)

Description

1. High rigidity Flexible rotation Accurate location

With the cross-roller bearing, cylindrical rollers are arranged with each roller perpendicular to the adjacent roller, in a 90° V groove, rollers, and grooves are linear contact, rings and rollers have small elastic deformation when the bearing achieves loads, thus, it has high rigidity. Separated from each other by a spacer or retainer to prevent rollers from skewing and the friction between rollers, improving flexible rotation and working speed.

2. Simple operation and Install

With the types of two-piece outer rings, inner rings type, integrated structure with roller putting holes type, which is very easy to operate and install.

3. Achieve loads in axial, radial, and tilting moment

With the structure of a 90° V groove, cylindrical rollers are arranged with each roller perpendicular to the adjacent roller, this design allows just one bearing to receive loads in all directions including radial, axial, and moment loads.

4. Save installation space

Since the Cross-roller Ring achieves high rigidity despite the minimum possible dimensions of the inner and outer rings, it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical equipment, measuring instruments and IC manufacture machines.

Catalogs

No catalogs are available for this product.

See all of THB Bearings‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Bearing unit

- Deep groove ball bearing

- Slewing bearing

- Double-row bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Ball bearing slewing bearing

- Cage assembly bearing

- Single-row slewing bearing

- Tapered roller bearing

- Angular-contact bearing

- High-speed bearing

- Industry bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.