- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

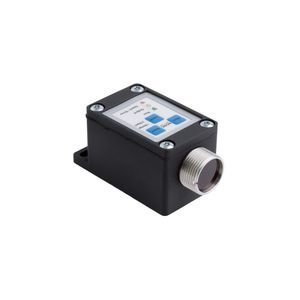

Electro-optical level switch OPT-PC for liquidspolysulfonestainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- electro-optical

- Medium

- for liquids

- Material

- stainless steel, polysulfone

- Mounting

- threaded

- Other characteristics

- compact

- Process temperature

Min.: -10 °C

(14 °F)Max.: 125 °C

(257 °F)

Description

An optical level switch works by emitting a beam of infrared light within a prism and measuring the amount of light received. When the measured fluid reaches the sensor the amount of emitted light received drops thus triggering the contacts. As the sensor is detecting the state between material covering or not covering the prism it can be used to detect the presence or absence of fluid thus preventing damage to pumps.

The compact unit houses the infrared transmitter, the prism, the receiver and the electronics, there is also an external LED indicator to show the condition of the switch. The sensor requires a power supply of between 10-28 Volts Dc. The benefit of the modern optical sensor is that there are no moving parts that can retain material and get clogged up or damaged, simply fit and forget.

The compact unit houses the infrared transmitter, the prism, the receiver and the electronics, there is also an external LED indicator to show the condition of the switch. The sensor requires a power supply of between 10-28 Volts Dc. The benefit of the modern optical sensor is that there are no moving parts that can retain material and get clogged up or damaged, simply fit and forget.

Product Feature

* High quality sealed unit with 2m lead

* NPN,PNP open collector output to energise relay or PLC.

* Enclosure material of PC (Polycarbonate), PSU (Polysulfone), 304 or 316 Grade Stainless Steel for acidity and alkaline; applicable in waste water, Wine, Vinegar solutions, liquor, alcohol....etc.

* Over current and reverse polarity protected

* LED Status indication

* Not reccomended for use where fluids may leave residue

Catalogs

No catalogs are available for this product.

See all of The Comus Group‘s catalogsRelated Searches

- Level limit switch

- Liquid level limit switch

- Pressure switch

- Mechanical pressure switch

- Protection level level switch

- Float level switch

- Stainless steel level limit switch

- Waterproof pressure switch

- Threaded level limit switch

- Adjustable pressure switch

- Plastic level switch

- Magnetic float level switch

- Solid level limit switch

- Compact level limit switch

- Compact pressure switch

- Pressure switch for hydraulic applications

- IP68 level limit switch

- IP67 pressure switch

- Pressure switch for pneumatic applications

- Polypropylene level switch

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.