- Products

- Catalogs

- News & Trends

- Exhibitions

Rotational speed sensor PICDTURN®-2G serieseddy currentcompact

Add to favorites

Compare this product

Characteristics

- Type of movement

- rotational

- Technology

- eddy current

- Other characteristics

- compact

- Frequency

1 MHz

- Temperature range

Max.: 270 °C

(518 °F)Min.: -40 °C

(-40 °F)

Description

Rotational Speed Sensors

Accurate Technologies Inc. (ATI) offers the PICOTURN 2G rotational speed sensor for turbochargers. Compared to optical or magnetic sensing systems, the PICOTURN system is proven as a rugged, reliable, simple, accurate and cost effective solution. , using a compressor mounted solenoid sensor that detects and counts compressor vanes individually, generating a standard TTL/CMOS output signal. Maximum wheel speed measurement is 400,000 rpm, with a minimum operating speed of 390 rpm.

The open system architecture and the modular system design allow an easy integration into existing measurement systems as a stand-alone solution or optionally with the PT2G-BD or PT2G-BX signal conditioning boxes. The preferred turbo compressor wheel material is aluminum; titanium wheels require individual testing to verify compatibility with the PICOTURN sensor.

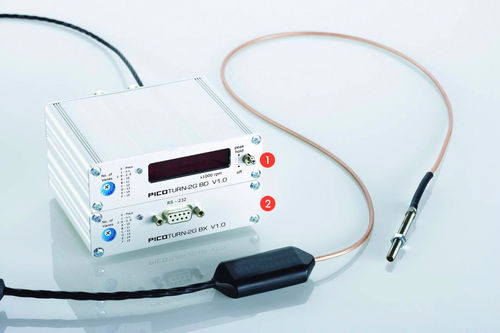

Signal Conditioning Box with display

Signal Conditioning Box with display - Ref. PT2G-BD

Signal Conditioning Box with D-Sub-9 (no display) - Ref. PT2G-BX

The PICOTURN system benefits from high sensitivity, allowing a large distance between sensor and the rotating vanes in the range of 1 at 0.6mm vane thickness. Various sensors are available to accommodate numerous user cases differentiated by the length and thread the sensor head.

2nd Generation Cable

Sensor body with M5x0.8 (standard) or M5x0.5 (fine pitch) thread, various lengths

Teflon coated, double shielded signal line

Molded body with ASIC based electronics inside

The PTSM-H series benefits from enhanced sensitivity, enabling use with titanium wheel and

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.