- Hydraulics - Pneumatics

- Pump

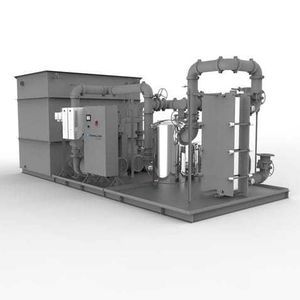

- Water pumping unit

- Thermal Care, Inc.

Water pumping unit PT seriesstationaryindustrial

Add to favorites

Compare this product

Characteristics

- Fluid

- water

- Mobility

- stationary

- Domain

- industrial

Description

Thermal Care offers a complete line of pre-engineered tank systems for cooling tower and central chiller applications with the highest quality design and construction features available. Standard, full sized pump trim, extended pump suctions legs, welded seams and solid steel decking under pumps and a PLC are just some of the value-added features incorporated into every system. Our selection of reservoirs, pumps, controls and alarms, plus complete engineering support from system design to plant layout drawings, assure you of the correct system for your application.

Overview

Available in fiberglass or stainless steel for indoor or outdoor installations

PLC for quick and easy operation

Premium-efficiency, close-coupled, non-overloading, centrifigual pumps provide optimum flow and pressure with reduced electrical costs

All pumps are mounted on a solid deck for added rigidity, serviceability, and safety

Grooved pipe connecting system reduces the need for flexible couplings and eliminates pipe stress at start-up; connections readily disassemble for fast maintenance and reconfiguration when adding or changing pumps

Full size pump suction legs on stainless steel tanks feature a 45° angle opening to prevent vortexing and pump cavitation, which can lead to pump damage and reduced pump performance

Liquid filled pump discharge pressure gauges enable accurate flow adjustment; isolation cocks prevent gauge pressure fluctuation and extend pressure gauge life

Factory mounted thermometer allows quick monitoring of process water temperature

Discharge check valve stops supply line flowback, eliminates the potential for water hammer at pump start-up

VIDEO

Catalogs

Pump Systems PT Series

4 Pages

Pump Tanks

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.