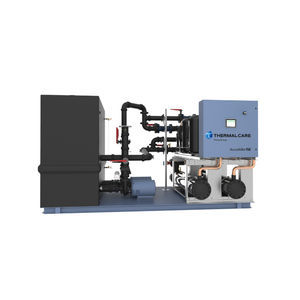

Water chiller TCFW seriesindustrialcentrifugal compressortechnology

Add to favorites

Compare this product

Characteristics

- Material

- water

- Applications

- industrial

- Other characteristics

- technology, centrifugal compressor

- Maximum temperature

Max.: 75 °F

(24 °C)Min.: 40 °F

(4 °C)

Description

Thermal Care has expanded its line of industrial TCF central chillers to include the TCFW375 ice rink chillers. TCF central chillers combine the efficiencies of both a hybrid film evaporator and a Turbocor variable speed centrifugal compressor to deliver optimum full and part load efficiencies. The result is one of the most energy efficient central chillers ever built.

Water cooled single circuit model

Advanced PLC System maintains stable and reliable operation of the chiller

Hybrid film evaporator for the most efficient heat transfer

Direct-drive variable-speed Turbocor centrifugal compressor technology continuously adjusts speed to match load and reduce operating costs

C-UL 508A listed and labeled industrial control panel

Rotary circuit breaker for compressor

Single point connection for electrical hookup at control cabinet

Only one major moving part - the compressor impeller which is used to compress gas and provides the highest full load efficiency and less energy use.

Integrated Variable Speed Drive Motor Control

Enhances temperature control capability for partial load performance.

Soft-start control reduces peak energy demand and extends motor life by lowering initial current inrush at start-up

Lowest noise level; whisper quiet sound levels with 74 dBA and virtually no structure-born vibration

Magnetic “Friction-Free” Bearings

Equipment life is extended since there is no contact with surfaces as the shaft rotates

Compressor senses a power failure as a normal shutdown. Internal capacitors and rotational

energy allow the motor to become a generator and provide a fail-safe shutdown.

Compressor shaft rests on a graphite-lined touchdown bearing when not in operation

VIDEO

Catalogs

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Industrial chiller

- Plate heat exchanger unit

- Compact chiller

- Stainless steel chiller

- Air-cooled recirculation chiller

- Water-cooled cooling system

- Air-cooled chiller

- Pressure chiller

- Outdoor chiller

- Gas chiller

- Water-cooled chiller

- Electric chiller

- Compressed air cooling system

- Screw chiller

- Cooling tower

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.