- Industrial machines and equipment

- Welding and Assembly

- Arc welder

- Thermatool Europe

Arc welder HF DC

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Output current

- DC

- Output frequency

400 kHz

Description

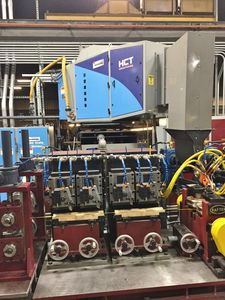

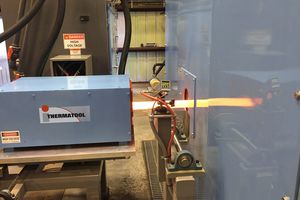

Produce high quality Spiral Fin Tube efficiently with our Solid State Spiral Fin Tube Welders.

Achieve these excellent benefits with a Spiral Fin Tube Welder:

Smoother output and improved weld quality

Weld more alloys more efficiently

Run higher RPM’s at lower kilowatt voltage

Less arcing and sparking with improved contact life

Use less power and water

Improved safety and less floor space

Reduction in scrap

FEATURES

Power Efficiency. Increased output efficiency, resulting in power cost savings

Reliable. Elimination of expensive finite life components such as the vacuum tube, RF output transformer and tank capacitors adds to increased reliability and up-time, and a significant reduction in maintenance costs.

Improve DC Ripple. Smoother output wave shape compared to to a vacuum tube welder. Less welder spatter and forge tooling wear.

Safety. Solid State welders operate at much lower voltages than vacuum tube units – not exceeding 1200 volts at full power assuring added safety operators and maintenance personnel.

Floor Space. Solid State welders are extremely compact, occupying minimal space. The power supply can be placed up to 1,000 feet away from the mill.

Improved contact wear. Due to less arcing.

Reduction in scrap. Due to improved automatic Speed Power Control, reducing unwelded fin areas when stopping and starting.

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Arc welder

- Metal welding system

- Precision welding system

- DC welder

- Compact welding system

- PLC-controlled welding system

- Steel welding system

- Custom welding system

- High-frequency welding system

- Aluminum welding system

- High power welding machine

- Copper welding system

- Inverter welding system

- Stainless steel welding system

- Automated welder

- Brazing oven

- Carbon steel welding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.