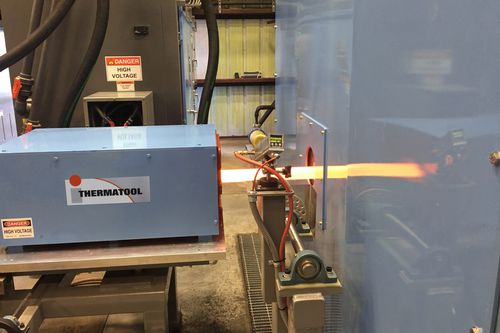

Thermatool’s Quench and Temper lines feature the most widely used and popular solid state induction power supplies available. With over 30,000 units installed worldwide for melting, heating, and heat treatment applications, the model VIP induction power supply is the most advanced technology accessible. In addition, Thermatool’s advanced precision slot quench has revolutionised the heat treat market and surmounted long standing limitations to tubular and bar quenching. Effective hardening and tempering requires the ability to deliver uniformly heated material to achieve optimum product straightness and minimal cracking through the quench. The combination of the latest computerised process controls in heating and quenching has benefited numerous industries that require quenched and tempered product. End users producing large pipe for the OCTG industry, food grade tube and pipe, and hardened and tempered bars are able to meet physical material properties demanded in many markets utilising the Thermatool quench and temper line.

Smart Heat Control

Thermatool’s state-of-the-art smart heat control technology offers the next generation in induction heat treat technology for pipe, tube and bar processing. Proven temperature control feedback and process modeling are integrated to achieve optimal hardening and tempering results. This technology allows the operator to maintain better control over heating rates and product temperature when using multiple coil (inductor) induction heat treat units. Thermatool’s smart heat intuitive control software promotes recipe creation and recall for repeatable process setups, control and results.