- Products

- Weld seam debeader

- Thermatool Europe

Weld seam debeader

Add to favorites

Compare this product

Description

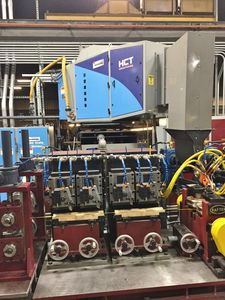

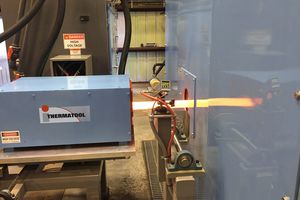

Thermatool’s globally proven and reliable Seam Annealing equipment is uniquely designed to effectively Post Weld Heat Treat (PWHT) HF welded tube and pipe across a wide range of product diameters, wall thicknesses and material chemistries. Providing successful and repeatable quality control and process repeatability, Thermatool Seam Annealers are available with SmartAnneal™ closed loop temperature control and real-time process monitoring. Powered by the metal industry’s most widely used and preferred VIP™ Series Power Supplies, Thermatool Seam Annealers offer the most comprehensive automation and control package (including recipe recall) available to mill operators today – while ensuring the most efficient delivery of power to the tube or pipe.

In addition to standard tube and pipe applications, Thermatool™ Seam Annealers can be fit to spiral products, engineered structural sections, and custom tubular profiles.

Inductor Design

The method of introducing the magnetic fields to the pipe is achieved through the inductor design. Thermatool uses two specially designed and proven options, a traditional or “V” shaped inductor, that can be used for focusing the magnetic fields to the pipe heat affected zone or “HAZ” for enhanced delivery and maximized efficiency. Thermatool engineers developed this proven design that is specially shaped to concentrate the fields into the pipe and minimize overheating of the area around the HAZ. Concentrating the fields to the proper area results in a more efficient power transfer.

Catalogs

No catalogs are available for this product.

See all of Thermatool Europe‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.