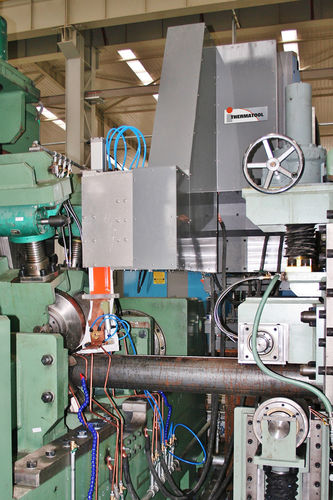

With the ever increasing energy costs worldwide, more large diameter pipe producers have been selecting Thermatool’s Solid State Dual Induction Welders. This provides the producer the knowledge of significant power cost savings upon welding larger diameters, with this more efficient process. Thermatool, the inventor of the HF contact welding process, has met the evolving requirements of API pipe production with Solid State Dual Induction Welders. With recent advances in power supply design, Thermatool has combined the best of both welding processes into one system.

FEATURES

Two processes in one welding system.

Quick Change capability. Switch between Induction/Contact via Selector Switch on Operator’s Console.

Contact/Coil modules simplify changeover process.

Meet demanding API pipe specifications with the induction process.

Achieve highest power cost savings with the contact weld process.

Achieve highest efficiency when welding hollow structural sections (HSS) or other products.