Control software SeamScan™calculationtrackingPLC

Add to favorites

Compare this product

Characteristics

- Function

- control, calculation, tracking

- Applications

- PLC, Ethernet

- Type

- real-time

Description

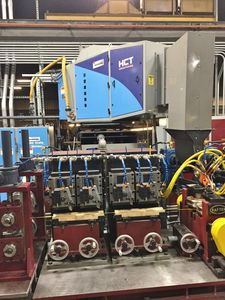

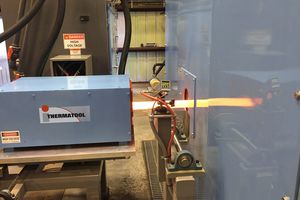

SeamScan™ is an advanced thermal seam tracking package designed for Thermatool Seam Annealers. The tracking equipment utilizes state-of-the-art thermal cameras and image processing technology to detect the HF welded seam. SeamScan™ automatically positions each annealer inductor over the weld seam to ensure accurate heating. This control platform consists of a thermal camera, image processor CPU, and a touch screen which communicates via ethernet to each seam annealer’s PLC (requires SmartAnneal™ option).

FEATURES

The software algorithm calculates the correct position for each annealer inductor along the hot seam, tracking the seam twist in the mill.

Annealer controls allow the system to automatically rotate the annealer inductor orbitally around the circumference of the pipe (6” pipe and larger).

Displays pipe angle and angle of each inductor.

The inductor position and seam angle are graphed in real-time (±15o seam twist maximum).

The product recipe can be saved for each pipe OD and air gap.

Recipe settings can be data-logged to a text file available for post-process review (export via USB or ethernet).

Eliminates unreliable line painting and visual camera painted line tracking system.

Catalogs

No catalogs are available for this product.

See all of Thermatool Europe‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.