Water cooler HYDROCOOL oilbearingcustom

Add to favorites

Compare this product

Characteristics

- Material

- water, oil

- Applications

- bearing

- Other characteristics

- custom

- Maximum temperature

120 °C, 180 °C

(248 °F, 356 °F)

Description

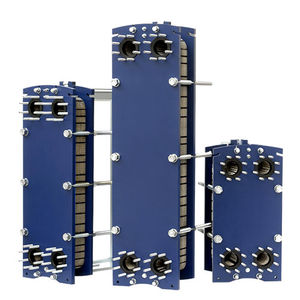

The guide and thrust bearing oil coolers allow cooling of the oil used in the guide and thrust bearings of the turbine and generator; oil which heats up due to the friction of the various moving parts. Through years of hands-on experience and the development with its partners of unique custom made solutions, Thermofin has been able to establish itself as a market leader in the design and manufacture of bearing coolers. Whether the heat exchange needs to be forced or natural convection, through single or double tube arranged to fit you specific geometrical requirements, Thermofin holds profound understanding of the heat transfer mechanisms insuring adequate sizing and efficient cooling. It will fit and it will cool. The Thermofin team can also refurbish your bearing oil cooler for easy maintenance by changing the configuration (number of sections) of your cooler. There are two families of bearing coolers : internal and external.

INTERNAL BEARING OIL COOLERS

Hydrocool exchangers usually have a circular shape for installation in bearing oil tanks. The bearing coolers ensure the cooling of the oil which circulates outside the tubes using river water which circulates inside the tubes. The thermal design of Hydrocool heat exchangers is generally based on free convection on the oil side, as oil velocities are often difficult to quantify accurately. Our guide and thrust bearing oil coolers can be designed with or without fins, depending on the space requirement. When using fins, Powerfin extruded aluminum fins are used which ensures a robust and durable design of your cooler. Internal bearing coolers can be designed in different configurations

Catalogs

No catalogs are available for this product.

See all of Thermofin‘s catalogsRelated Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Industrial heat exchanger unit

- Oil chiller

- Shell and tube heat exchanger

- Custom chiller

- Gasketed plate heat exchanger

- Dry cooler

- Small heat exchanger

- Transformer cooling system

- Finned tube cooler

- Exchange coil

- Steam exchange coil

- Finned tube

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.