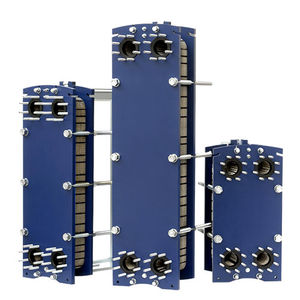

Shell and tube heat exchanger caleosliquid/liquidindustrial

Add to favorites

Compare this product

Characteristics

- Type

- shell and tube

- Fluid

- liquid/liquid

- Applications

- industrial

Description

The physico-chemical properties, the phases (liquid, gaseous or solid) and the corrosivity of the fluids involved in industrial processes are extremely varied. The heating or cooling of such fluids requires a flexible and efficient exchanger technology. The standardized exchangers cannot meet all the constraints present in these very particular processes. The Thermofin shell & tube heat exchangers are custom-made, thus integrating many specific features to perfectly meet your needs.

DETAIL

A typical schematic of a shell & tube heat exchanger, also called multitubular heat exchanger, shown below. This type of heat exchanger consists of a tube bundle inserted inside a shell. One of the fluids circulates inside the tubes and the other around them inside the shell. The number of baffles and their geometry are optimized in order to improve the heat transfer. Front and rear channels are attached at each end of the bundle, ensuring the distribution of the fluid inside the tubes. Their configuration may be for one or more passes in order to control the fluid velocity inside the tubes. In the shell side, the fluid circulates outside the tube bundle along the path imposed by the baffles. The diameter of the tubes is also optimized depending on the nature and quality of the fluid.

OPTIONS AND CONFIGURATIONS

The main advantage of the shell and tube technology is to offer a wide range of configurations to meet your expectations. The operational constraints of the process are taken into account by our engineering team, highly specialized in thermal and mechanics, in order to propose the right heat exchanger configuration.

Catalogs

No catalogs are available for this product.

See all of Thermofin‘s catalogsRelated Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Industrial heat exchanger unit

- Oil chiller

- Shell and tube heat exchanger

- Custom chiller

- Gasketed plate heat exchanger

- Dry cooler

- Small heat exchanger

- Transformer cooling system

- Finned tube cooler

- Exchange coil

- Steam exchange coil

- Finned tube

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.