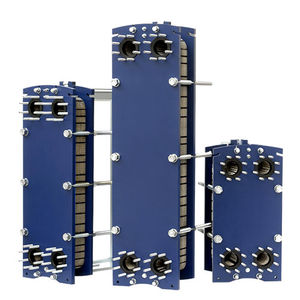

Liquid cooler ELECTRAfor alternatorfor electric motorsfinned tube

Add to favorites

Compare this product

Characteristics

- Material

- liquid

- Applications

- for alternator, for electric motors

- Other characteristics

- finned tube

Description

Allowing access to the tubes internal surfaces, the ELECTRA generator coolers and motor coolers (TEWAC) are ideal for use with corrosive fluids or heavy fouling process. The tubes interior may then be cleaned periodically; insuring improved efficiency and longevity for your exchanger. In addition to the use of water boxes as inlet and outlet collectors, numerous thermal configurations are possible in order to always better optimize the heat exchange between the two fluids.

Thermofin’s generator coolers and motor coolers may be designed to meet the prescriptions of the ASME Code, and even more restrictive specifications such as the american military specifications or those of some of our reknowned clients. Accordingly, Thermofin’s unit may bear the ASME “U” or “UM” Stamp, the China Licence number, or they may also be registered with quality control agencies such as the American Bureau of Shipping (ABS), the National Board (NB) and other regional jurisdictions (CRN).

The reliability of an exchanger rests on the judicious choice of materials and on sound design. A good example of this is found in Thermofin’s dedication to reliable and durable leaktightness of water box covers via the systematic application of O-ring joints (made of neoprene, silicone, buna-n or other suitable joint materials) in the design of our generator coolers. This feature and others like floating tubesheets, expansion joints and our famous aluminum extruded finned tubes make the ELECTRA heat exchangers a highly technological equipment made to provide long term quality sustainable service.

Catalogs

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Industrial heat exchanger unit

- Oil chiller

- Shell and tube heat exchanger

- Custom chiller

- Gasketed plate heat exchanger

- Dry cooler

- Small heat exchanger

- Transformer cooling system

- Finned tube cooler

- Exchange coil

- Steam exchange coil

- Finned tube

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.