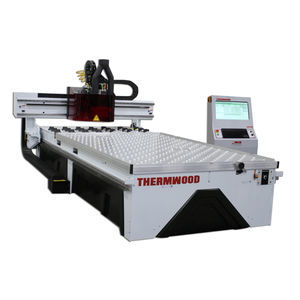

CNC router FRAMEBUILDER 483-axisfor woodwith automatic tool changer

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Treated material

- for wood

- Other characteristics

- with automatic tool changer

Description

Complete three axis CNC routing system to machine nested upholstered frame parts from sheet stock. The moving gantry, fixed table with roller hold down system is designed for routing and stack machining. This system is suited for machining 4'x8' sheets of plywood.

Available Table Sizes: 4'x8'

18 HP HSD Spindle (3,000-24,000 RPM).

Fixed Solid Aluminum Table with Moving Gantry

Roller Hold Down System

Automatic Load/Unload System

Table Dust Collection

Programmable Side Bars & Locator Pin

Automatic Lubrication (Optional)

Automatic Tool Length Measurement (Optional)

Three-Dimensional Laser Compensated Axis Alignment

Control Nesting

Siemens Intelligent Servo Drives Throughout

QCore SuperControl

Machine Training and Installation

18 HP (13 kw) Spindle

The 18HP (13 kw) spindle (3,000 to 20,000 programmable RPM). Accepts HSK F63 toolholders as well as Thermwood Aggregates and is equipped with an electric fan.

Roller Hold Down System

Roller Hold Down System is a series of urethane covered steel rollers which are pressed to the spoilboard by air cylinders. the router travels between the rollers during the machining operation. This system works well with rough plywood or stacked sheets of material.

Automatic Load/Unload System

An automatic load/unload system is available to automate the process of loading the sheet material onto the machine table and automatically off-loading the parts to a sorting table upon completion.

Catalogs

No catalogs are available for this product.

See all of Thermwood‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.