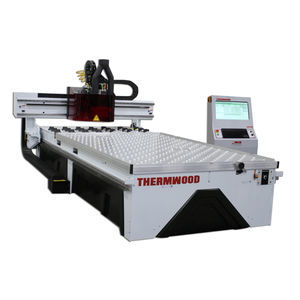

CNC router AUTOPROCESSOR 433-axisspindlefor wood

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Number of spindles

- spindle

- Treated material

- for wood

- Other characteristics

- with automatic tool changer

Description

Thermwood's AutoProcessor 43 Machining Center is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

The AutoProcessor 43 is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Labels each part area on the sheet

Moves and automatically positions the sheet on the table

Machines the material while labeling the next sheet

Simultaneously off-loads the finished parts and reloads the next sheet

Continuously repeats the process

STANDARD FEATURES:

5'x10' (1.5m x 3.0m) Fixed Table

Moving Gantry

10 Position Automatic Rotary Tool Change System

12 HP (9kw) ISO Electro Spindle

High-Flow Vacuum Table

Automatic 6000 LB Lift Table for Loading

Simultaneous Automatic Labeling System

Automatic Dust Extraction During the Unload Raking Process

Automatic Pop Up Pins

Automatic Tool Length Sensor

Automatic Lubrication System

Automatic Sheet Load/Unload System

Automatic Sheet Positioning System

Siemens Intelligent Servo Drives Throughout

3D Laser Compensated Axis Alignment

SuperControl

Control Nesting

5 Spindle Drill Bank (Optional)

Unload Sorting Table (Optional)

Touch Screen Control (Optional)

WELL EQUIPPED WITH FEATURES/OPTIONS

12 HP (9KW) SPINDLE

A direct driven spindle with a speed range up to 24,000 RPM. the High Frequency Spindle is cooled with an electric fan for quieter running and contains ceramic bearings for longer life and for less maintenance.

Catalogs

No catalogs are available for this product.

See all of Thermwood‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.