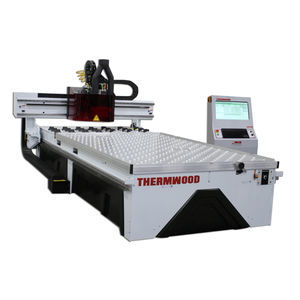

CNC router CABINETSHOP MTR3-axismulti-spindlefor plastics

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Number of spindles

- multi-spindle

- Treated material

- for composites, for plastics

- Other characteristics

- with automatic tool changer

Description

Complete three axis CNC routing systems with single or dual in-line tables for nested base, composite or plastic sheet material.

Available Table Sizes: 5'x10' (1.52m x 3m), 5'x12' ( 1.52m x 3.6m), 7'x12' (2.1m x 3.6m), 7'x20' (2.1m x 6m)

12 HP HSD Spindle (3,000-24,000 RPM). Optional 18 HP Spindle

Fixed Single Steel High Flow Table with Moving Gantry (MTR 21, MTR 30, MTR 36 and MTR 60)

Dual, Fixed Steel High Flow In-Line Tables with Moving Gantry (MTR 30DT)

10 Position Bar Style Automatic Tool Changer (MTR 21 Single Table)

16 Position Bar Style Automatic Tool Changer (MTR 30, MTR 36 and MTR 60 Single Table)

15 Position Bar Style Automatic Tool Changer (MTR 30 DT, Dual In-line Table)

At the Head Automatic Tool Changer (Optional)

Automatic Tool Length Measurement

Three-Dimensional Laser Compensated Axis Alignment

Control Nesting

Siemens Intelligent Servo Drives Throughout

QCore SuperControl

Machine Training and Installation

12 HP (9kw) Spindle

A direct driven spindle with a speed range up to 24,000 RPM. The high-frequency spindle is cooled with an electric fan for quieter running and contains ceramic bearings for longer life and for less maintenance. The 12 HP (9kw) spindle provides the user with a heavy duty, precision spindle which provides high performance and reliability.

15 Position Bar Style Automatic Tool Changer

Mounts between the two tables and holds the tapered tool holders. When the program calls for a tool change, the head moves to the holder and places the tool into an empty space, it then moves over and picks up the appropriate tool, and then continues the program.

Catalogs

the CabinetShop MTR

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.