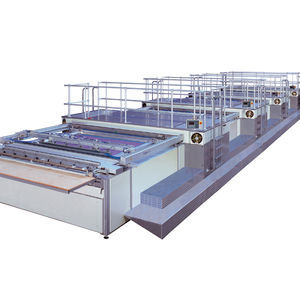

Fully-automatic screen printing machine 5000 seriescolorhigh-accuracyhigh-speed

Add to favorites

Compare this product

Characteristics

- Control

- fully-automatic

- Number of colors

- color

- Other characteristics

- high-accuracy, high-speed

Description

Fully automatic screen printing system with rotary grippers. Precision built, short set-up times. Absolute reliability for multi-shift operation. High precision and speed through servo drive motors.

• Maximum volume output, also for different formats and materials

• Short set-up times

• High precision and speed through servo driving force

• Machine job data storage memory

• Complete machine programmable

Why THIEME 5000?

• Fully automatic with manual loading opportunity

• High flexibility of the substrates from 0.1 to 6 mm

• Short setup times by tool-free setting

• Fast Investment amortization due to low staffing

• Highest Productivity

• Absolute reliability in multi-shift operation

• Thieme-Quality „Made in Germany“

Specifics

• Material handling by circulating gripper system

• Automatic sheet positioning

• Precision and speed through servo drive technology

• Printing parameters stored for recurring print jobs

• Exceptional print results from THIEME designed table and original THIEME Squeegee Unit

• Loading / unloading on pallets

• Durable machine concept, usable as a ¾ auto- machine

• Individual selection of a machine options based on customer requirements

• Extensive Feeder options (single sheet, scale, leading / trailing edge)

VIDEO

Catalogs

No catalogs are available for this product.

See all of THIEME‘s catalogsRelated Searches

- Printing machine

- Stencil printer

- Automatic stencil printer

- Color label printer-applicator

- Color screen printing machine

- Automatic label printer-applicator

- Flat bed stencil printer

- Inkjet printing machine

- Electronic stencil printer

- Screen printer for the glass industry

- Monochrome screen printing machine

- High-speed screen printing machine

- Semi-automatic stencil printer

- High-accuracy screen printing machine

- Textile screen printer

- Fully-automatic screen printing machine

- 4-color printing machine

- 2-color screen printing machine

- 4-color screen printer

- Large-format screen printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.